Regenerative practices that are less reliant on artificial inputs require farmers to select varieties with attributes that can help them thrive in such conditions.

It is something East Yorkshire farmer, Jonathan Hodgson of I M Hodgson & son Ltd, recognises, after converting the 280 ha farm, to a reduced input, strip tillage system in 2019.

There is a diverse rotation on the medium to heavy clay farm, east of Hull, featuring winter wheat, oilseed rape, spring barley, spring oats, winter beans, vining peas, flax, and herbal leys. Cover crops are grown ahead of spring crops, while short-term catch crops are also included wherever possible, namely after vining peas, or oilseed rape, ahead of wheat.

“We’re trying to build diversity into the rotation, but our primary focus remains on first wheats; that’s what we’re always trying to get back to as quickly as we can,” says Mr Hodgson.

This season, he is growing a range of varieties, including 20 ha of the hard Group 4, LG Typhoon, alongside LG Astronomer for seed, trial areas of LG Aldaniti and LG Redwald, plus Costello, KWS Extase, Theodore, and a four-way blend trial.

It is the second year of growing LG Typhoon, after a successful 3 ha trial of the variety last year, on land previously in pasture.

Desirable traits for regen

Mr Hodgson’s decision to grow LG Typhoon followed a conversation with Limagrain UK’s arable technical manager, Ron Granger, who says the variety has certain attributes that suit strip tillage/ direct drilling, regenerative crop establishment systems.

Mr Granger says LG Typhoon had been on the farm in a Limagrain UK demo trial, alongside commercial and up-and-coming varieties, for a couple of seasons, and it was clear the variety offered better suitability for the direct drilling, wider row situation.

“It was a stand out variety,” says Mr Granger.

LG Typhoon’s growth habit, for example, means plants sit prostrate with slower growth through the winter into spring, which is ideal for those direct drilling earlier in the autumn and do not want a variety that will race off too quickly.

It is high tillering and has the capacity to utilise the space between the wider rows, often found with some direct drilling equipment. Indeed, Mr Hodgson’s Mzuri drill has a relatively wide row spacing of around 300 mm centres.

LG Typhoon’s strong standing power and disease resistance – reflected by its high untreated yield (92%) – further suits those looking for flexibility with crop protection inputs, Mr Granger says. Unlike some feed varieties, it also offers Orange Wheat Blossom Midge (OWBM) resistance, in addition to a six-rating for eyespot and Fusarium.

“It’s a high yielding, consistent and resilient variety, that delivers across seasons and rotations.”

For Mr Hodgson, the biggest draw is LG Typhoon’s robust disease package, particularly the Septoria rating of 7.3, and yellow rust rating of 9.

“That’s what I look for in a variety, probably more so than outright yield. What can it offer in terms of agronomy, and is it a good, stable, variety that will let me look after a crop how I want to, instead of relying on a can to keep it clean?”

Cutting inputs

Last year’s LG Typhoon lived up to promises, yielding 11 t/ha from limited inputs – about 10% up on the farm’s five-year average yield.

The crop received two fungicides – 0.5 L/ha Amistar (azoxystrobin), and 1 L/ha Verydor XE (fluxapyroxad + Mefentrifluconazole) – and a total of 160 kg N/ha.

“We have been trying for a number of years to reduce fungicide inputs, but last year was the first time we’ve done so on a farm-scale, albeit helped by relatively low disease pressure.”

Indeed, one variety on the farm did not receive any fungicide inputs in 2022, and still yielded over 10 t/ha. Other crops did receive fungicides at different stages of the season, reflecting Mr Hodgson’s desire to remain flexible and adapt to the conditions.

“We want to be flexible. If the plant looks healthy, I won’t put a product on, but if it needs one, we will still use a fungicide. Last year, some crops had a T1, others got a T2, and some first wheats had a T1.5 instead of a T1, as that’s when we decided to go on. We won’t rule out using fungicides, but it’s a measured approach, field-by-field and variety-by-variety.”

While looking to reduce reliance on fungicides, Mr Hodgson is keen to support plant health in other ways, notably through more targeted nutrition, utilising in-depth soil testing, and sap analysis, to determine requirements.

He is also changing the way nitrogen is applied, by moving to a “little and often” approach, rather than applying large amounts in one go, which can cause surges of weak growth fuelled by simple sugars, potentially making plants more prone to lodging, and attack by pests and disease.

This approach typically sees 160 kg N/ha applied in four liquid applications of 40 kg N/ha every 15-20 days, from early to mid-March onwards. A carbon source is included with each nitrogen application to improve uptake efficiency. Programmes are completed with a final foliar nitrogen application. “This only provides about 10 kg N/ha, but the nitrogen use efficiency is far greater than applying nitrogen to the soil,” notes Mr Hodgson.

“Our aim is to keep plants healthy and growing at a consistent, steady rate, instead of causing surges of growth that need to be managed with PGRs.”

Additional fertility comes from the 1,100 tonnes of pig manure produced on the farm each year, applied on a rotational basis.

Supporting establishment

Mr Hodgson acknowledges that in the first years of converting to strip tillage, establishment was lower than with conventional tillage, as soils took time to adjust.

Seed rates were therefore increased to compensate. This season’s 20 ha block of LG Typhoon, was sown at 400 seeds/m2 on 27 September, after oilseed rape, using home-saved seed, with no dressing (just cleaned in a mobile seed plant and tested for fusarium).

“However, we are now seeing an improvement in soils and drilling conditions, so I think we can start to reduce seed rates slightly. It’s been a steep learning curve.”

To support crop establishment and soil health, Mr Hodgson also includes two liquid products – fish hydrolysate and humic acid – in a band with seed at planting. “The hydrolysate is full of amino acids, so the idea is to prime the soil by helping the biology.”

No starter fertilisers are used, and he points out that no phosphate or potash has been applied for the past four to five years. “Most soils have tonnes of P and K; we just need to be better at getting plants to access it.”

Mr Hodgson says this year’s LG Typhoon established very well in a relatively kind autumn and winter, growing on well through spring. Disease-wise, it looks “pretty clean”, despite having not received any fungicide, or growth regulator, up until the time of writing (beginning of May).

“There is more disease pressure this year than last, so we’ll have to remain on the ball and keep checking crops.

“It generally takes two to three years to get to know a variety properly, so it is still early days, but so far, LG Typhoon seems to suit our system.”

LG Typhoon

High yielding, consistent Group 4 feed wheat

Strong disease resistance, particularly Septoria (7.3) and yellow rust (9) – 92% untreated yield

OWBM resistance, good standing ability

Adaptable drilling dates – suits early drilling, also excellent as a second wheat

High tillering capacity and a slower, prostrate growth habit through winter into spring, and the plant’s ability to fill space, suits wider row direct drilling re-gen systems.

LG Typhoon

Meeting the challenges of growing oilseed rape has brought the value of both genetics and crop management practices into the limelight more than ever before. We look at how two growers on opposite sides of the country use these tools to tackle their challenges.

Despite the challenges of flea beetle, slugs and pigeons, oilseed rape is a good break crop for Emma Fletcher who farms 700 ha with her brother on the Leicestershire/Warwickshire border.

“It fits well in the rotation as a profitable break crop, going in after winter barley and before wheat”

The oilseed rape at Burton Fields Farming Ltd is was established via direct drilling with a 9 meter Dale direct drill. “The aim is to drill the crop in August, but the most important thing is to drill into moisture.”

“We have a tick list for the characteristics and traits a variety has to offer,” says Ms Fletcher. “Fundamentally we need it to be consistent, we don’t want a volatile crop that yields well one year and then lets us down the next.”

Emma Fletcher

“Aside from robust agronomics, we also need it to have really good autumn vigour, good disease resistance and we also look for a variety that offers pod shatter.”

“Aurelia ticks all of the boxes, and we were pleased with it in our first year of growing it in 2021 & 2022. We look for the rape to yield 4+t/ha.

“This year’s crop was drilled slightly later than we would have liked which meant it went in at the beginning of September rather than the last week of August, as we held off for a bit more moisture,” she explains.

“We had a few issues with CSFB in the spring. Despite drilling at low seed rates some areas have come through thicker than we would have liked, which we put down to volunteers, and the beetle seem to favour this thicker crop.”

Emma explains that having split hopper on the drill allows for companion crops to be sown at the same time. “Last year we established the OSR with buckwheat. Every other coulter was buckwheat or oilseed rape. We were really pleased with the results and the buckwheat then died off with the first frost.”

“However, this year the OSR has been drilled with a mix of buckwheat and berseem clover, so we shall see if that has made a difference.”

Nutrition at Burton Fields Farm is on a responsive approach with tissue tests being taken season-long and we prefer to respond to these results rather than simply going on with a blanket approach, points out Miss Fletcher.

“This season we have kept it fairly simple with the disease control and tried to utilise nutrition as best possible. In the autumn sewage sludge is put into the seedbed to enhance autumn vigour.”

“Slugs are often a problem in the autumn so traps are used to treat when the threshold is met. PGRs at this time are also very important; sheep have been considered instead of this but there are downsides to using them so we are holding back for now.”

Over in the north west of the country, Richard Reeves of Tattendale Farm has been growing OSR for 40 years.

“We are a fairly traditional arable rotation on a tenancy agreement with Tatton Park Estates, of which OSR is an integral part. We look for yields on average of 4.5t/ha and prefer varieties that we can rely on for a consistent yield.”

“On the advice of our rep, James Hood from United Oilseeds , we opted for Aurelia a couple of years ago and will stick with it again this coming season as it has delivered what we need. It comes though well in the autumn, its vigour is stand out and we haven’t had any issues with disease.”

Aurelia

“We tend to keep things fairly simple as this has always worked for us. The OSR follows barley or early wheat,” says Mr Reeves.

“Waiting for moisture to drill in the autumn is not so much of an issue where we are so we aim to drill in the last two weeks of August, any earlier and we find the crop gets too proud.”

“As we are not in a predominantly arable area, CSFB is not so much of an issue, pigeons are our challenge.”

Our soils take the plough well, so we plough and combo drill the rape straight after, which traps the moisture with the seed.”

Seed rates are around 3kgs/ha. We apply about 140-150kg/ha Nitrogen across two applications of granular product and then top up with liquid. This year we are looking at going on twice with a foliar application as we have found that this increases the oil content. We also apply Sulphur in an N:S mix.

“A single PGR is used in the autumn, and a fairly standard fungicide programme as we have so few disease issues with the Aurelia.“

“At the end of the day farmers want yields as this is what they get paid for, so growing a variety that the best chance of reaching its yield potential is key,” says Liam Wilkinson of breeders Limagrain UK.

“Growers can put in all the leg work, but are still being thwarted by elements beyond their control, which is where plant breeding steps in to protect yield by breeding stacked traits into varieties,”

Beckii Gibbs, seed manager with United Oilseeds, believes that Aurelia’s offering of fully loaded traits, excellent disease resistance, proven performance and good vigour makes it a firm favourite with farmers.

“Aurelia has been the number 1 variety on farm for a number of years now. The fact that it holds a 30% share of the UK certified hybrid seed market speaks volumes. From our farmers’ perspective, it’s a reliable and consistent variety and is likely to remain a popular choice particularly with the good yields Aurelia achieves year on year.”

LG GatePost Newsletter – June 2023The June 2023 issue of LG GatePost is now available to download.

This edition features articles about our newest wheat addition to the 2023-24 AHDB Recommended List, LG Redwald, as well as LG Caravelle, our excellent 2-row winter feed barley.

You can read about and view our Live Panel event which was a round table discussion on Varieties, Soils and Policy with industry experts.

We discuss the new Sustainable Farming Incentives and the new ‘actions’ involved, with an article about why to consider establishing a legume fallow.

There is also information about our upcoming Demo Days and a link to register.

LG GatePost – June 2023

In the spring, Limagrain took a group of UK growers to Denmark, to look at regenerative and conservation agricultural practices.

After two full days of visiting farms, agronomy companies and a plant breeder, there was some very interesting and surprising feedback:

GEORGE ATKINSON, LINCOLNSHIRE: “It’s been fascinating to see all the different farming systems, and also learn about Danish policies that contradict themselves. I was expecting to come and see the future, but some of the growers are where we were 15 to 20 years ago.”

AL BROOKS, HAMPSHIRE: “I came here with a preconceived idea that we were going to learn something from the Danes in terms of their view towards conservation and regenerative agriculture. I was stunned by the amount of red tape they are subjected to. They are constricted in the industry and don’t have the voice with government.”

TIM PARTON, STAFFORDSHIRE: “I think the government advisors in Denmark need to take a real hard look at what they are trying to achieve, and what their directives are. They are so restrictive; they are missing out on the big benefits they could be getting from regenerative and conservation agriculture. They need to help their farmers more, rather than restrict them.”

“Discovering that UK farming practice with regards to conservation agriculture or regen is ahead of Denmark, was a surprise to many on the trip, and a real positive take home message for the UK.

It’s very noticeable that plant breeding is paramount to the future direction of agriculture, as practices move towards lower input and better disease resistances. Limagrain look forward to sharing what we do with growers from the UK and abroad,” says Tom Barker of Limagrain, who hosted the trip.

Download the latest edition of LG GatePost here

Consistency is key to sugar beet successSugar beet plays an important part in the rotation because it provides consistent yields and is a genuine break crop, according to fourth generation farmer Peter Mahony, of R&D Mahony.

“We grow sugar beet because it is a spring-sown crop that contributes to weed control, particularly black grass, which can be problematic as our soils are mainly heavy clay which predisposes them to the weed.”

Mr Mahony’s variety of choice over the past three years has been BTS 1915, which he likes because it ‘ticks the box on consistent yield’. He has also grown BTS 1140 and BTS 3610.

“BTS 1915 fits well with our system despite the variety being susceptible to bolting, as we are growing the crop in heavy soils, so we do not usually drill until the second half of March.”

The Bury St Edmunds-based farm has been growing sugar beet since the mid-1960s, so there is plenty of crop management experience behind decisions, although Peter emphasises that every spring brings different challenges.

Sugar beet usually follows winter wheat and Peter’s strategy is to plough in the autumn, burn off volunteers with glyphosate, repeat this again in the spring and create a nice seedbed with good tilth.

His five-year average yield is 73t/ha, he reveals, remarking that this is a good result given the heavy soils the crop is grown in. However, last year, yields were lower due to the drought and beet moth issues.

“Whilst we have a had a few dry springs, this year we are also coping with March and April being unreasonably cold and very wet.

“Whilst we have a had a few dry springs, this year we are also coping with March and April being unreasonably cold and very wet.

“But we have to work with what we are given, and beet drilling was split with 7ha drilled on the 5th April and the remainder 18-19th April.

“We planted into very wet seedbeds, so we kept drilling depths shallow to conserve the tilth on the top.”

By the third week of May the crops were at the four to eight-leaf stage, and looking very healthy.

Peter goes on to share some of his ‘secrets’ of how he addresses some of the inherent challenges to get the most from sugar beet crops on his land.

“We find that quite often it can be too hot in the day to apply herbicides, so we prefer to go in the evening.

“If the machinery has been used for spraying cereals, we make sure it is given a good clean before it goes into sugar beet to prevent contamination.”

He has also adjusted his fertiliser strategy for sugar beet, to ensure the best results.

“When the crop emerges we like to apply 80kg/N/ha to give it a good push. However, although we use liquid N on the other crops in the rotation, it can cause scorch on sugar beet and also interfere with herbicide efficacy.

“As a result, we buy solid fertiliser especially for the sugar beet, which, as it is bought in small quantities, is expensive, but the end result is worth it.”

Lifting sugar beet can cause soil compaction which needs remedial work before the next crop goes in and Peter points out that the harvester, which weighs 40t, plus the tractor and trailer are all on the field at the wrong time of year.

“We normally try to have just two or three lifts, and then go into spring barley.”

“However, last year we managed to lift in mid-October, which worked well.”

One of the reasons behind this early lifting was because there was an attack of beet moth; last year also saw challenges from heat, drought and aphids.

“With BTS varieties, and particularly BTS 1915, we are able to achieve consistent yields. This means we know what we are going to get, even when prices are not so good.

“However, as we are now changing our tillage strategy, and will be using a Claydon drill, we will have to evaluate where – and whether – sugar beet will sit with the new regime.”

Farm facts:

Home farm: 133ha (330 acres)

Contract farm: 81ha (200 acres)

Soil: Heavy clay

Current rotation: Winter barley, winter wheat, beans, sugar beet, spring barley

Highest yields for third year running

The highest yielding variety on the Recommended List, BTS 1915 keeps its lead for the third year running at 103.9%.

“BTS 1915 is once again showing its ability to hold onto its exceptional yields across a range of locations and situations.”

“The consistency of performance of BTS 1915 is quite remarkable, and should give growers the reassurance that they are looking for when considering what variety to grow this year.”

“This significant yield advantage over any other variety on the RL – and also as the highest yielding variety in untreated trials at 106.5%, really proves the quality of the genetics behind the variety,” says Mr Granger.

BTS 1915 is not just about high yields however, he continues. “We recognise that varieties also need to establish well, have good bolting tolerance and robust disease resistance to succeed.”

BTS 1915 does have a good disease resistance profile but is not a variety to be considered for the early drilling situation as indicated by the red X (unsuitable for sowing before mid March), points out Mr Granger.

“We recommend the variety for the normal to late sowing period – mid March onwards, which for the majority of growers is the mean average drilling date on farm. ”

BTS 1915 Facts

• Bred by Betaseed, the Limagrain UK portfolio offers varieties to suit a range of situations and requirements:

• BTS 1915 – The highest yielding variety available

• Suitable for sowing Mid March onwards

• Good disease resistance

Find out more about our sugar beet portfolio here

Download the Betaseed Sugar Beet Variety Guide

Achieving High OSR Yields Despite the ‘Weather Gods’For David Fuller-Shapcott who farms near Kelso in the Scottish borders, beating the weather is a constant challenge.

“Autumn’s are very short and wet, which means we battle to get crops established and it can be difficult to travel in the spring so spray timings can also be difficult. Whilst at the other end of the season we need to leave crops in the field that bit longer to maximise sunlight and keep biomass growing for as long as possible,” he explains.

However adapting cultivation and establishment techniques, a focus on soil health and a large amount of patience has brought success to the cropping at Sweethope Farm.

Mr Fuller- Shapcott’s crop of Ambassador oilseed rape took the Bronze award in the 2022 national ADAS YEN competition yielding 7.33t/ha. This is not his first YEN win for oilseed rape, in 2019 he won a YEN Bronze award for a crop which yielded 6.4t/ha, calculated as 63% of its yield potential.

Oilseed rape is the main autumn break crop at Sweethope Farm in a rotation that maximises first wheats. Oilseed rape is grown one in six which usually means about 45-50ha is grown in any one year. Spring barley is grown for the local distilling market and winter barley for brewing. Soils are heavy clay and run up to over 200m above sea level.

The farm also features 32ha of permanent grass used as grass park lets for cattle and sheep, plus 17ha of mixed woodland.

YEN 2022

Oilseed rape establishment at Sweethope is based on a cultivator, using nine narrow and shortened subsoiler tines, to create relatively undisturbed slots ahead of a heavy packer. A row of 9 disc coulters and covering tines follow the packer.

The crop entered for YEN in 2022 was drilled into a field of fairly virgin oilseed rape soil following winter barley after five years of grass.

“This meant less slug pressure, which can often be more of an issue than CSFB, with our heavy, cold soils. As it was after grass we didn’t have a cover crop in this particular field,” says Mr Fuller- Shapcott

“The crop was drilled on 27th August at 2.2kg/ha -targeting 20-25 seeds/m2 – the aim is to have 22 stems/m2 at harvest. I am looking for large single plant, not a field of cress,” he says.

“I chose to grow Limagrain’s hybrid, Ambassador for several reasons.”

“We moved into hybrids for their vigour in the autumn. I don’t want too much vigour in the spring when I cannot travel and keep up with the crop.”

“It’s not just one of the highest yielding varieties on the AHDB Recommended List, but also offers a very high oil content and this boosts gross output. I have found varieties with inherently low oils harder to push.”

“Good light leaf spot resistance up here is key and Ambassador offers one of the highest resistance ratings of 7. It also offers pod shatter resistance which is very valuable.”

Mr Fuller-Shapcott points out that Ambassador also offers N-Flex which minimises yield losses in sub-optimal N conditions, making a variety adaptable for both high and low input scenarios.

He was interested to see what the benefits of this would be on his own soils and nitrogen regime, so in 2021 he carried out a small farm nitrogen trial looking at rates and timings between Ambassador and sister variety Aurelia, that does not offer N-Flex.

He found that at lower nitrogen levels, Ambassador performed as well as Aurelia at normal nitrogen levels.

David Fuller-Shapcott

He believes that this provides the crop with flexibility. “If ground conditions are too wet or the weather closes in before we can get on with fertiliser in the spring, we are not compromising the potential of the crop too much- it gives us that really valuable leeway.”

Mr Fuller-Shapcott enjoys being part of YEN and believes the learnings from it are incredibly valuable.” YEN has taught me importance of canopy structure in oilseed rape and how to manage this to achieve a particular yield and we work to this. We know that if we have 100,00seeds/m2 and a 5.0 TSW we are looking on average at a 5t/ha crop.”

“To achieve this we want to influence the structure of the canopy to promote podding at the top, aiming for an ‘oak not a pine’,” he says.

“I take a very much balanced approach to crop nutrition – not pushing the crop too hard but enough to produce a decent output with justifiable inputs. I have learned from YEN that it is worth feeding the crop well from the beginning; little and often.”

“For this crop I was aiming for about 160kgN, but in fact ended up applying less, only 133kg but this does not appear to have impacted the crop performance – and we put this down in some part to the N-Flex ability of the variety.”

“Fertiliser in liquid form is applied down the spout at drilling (subcasting), which increases rooting. Spring nitrogen goes on as soon as its possible to travel. For this crop that was around the 20th March when 66kgN went on.”

“On the 12th April we applied the same again, both doses using a 30%N and 9% sulphur liquid (W/V) with trace elements.”

“With OSR we always make sure there is adequate Boron, and tissue testing through the season gives me an insight into what the plant needs at different times,” he says.

Disease control is started as soon as he can travel, with a keen eye on Light Leaf Spot. “Last season the first spray was around the third week of January, this was followed up on the 18th April with a PGR and fungicide, and again at the end of flowering.”

“Magnesium, phosphorus and potash, also went on at this timing to help build seed size.”

Mr Fuller-Shapcott doesn’t rush to desiccate. “If we think the crop is ready, we try and leave it for another week – which does require a large amount of patience! But we have found it pays off, as it means we never have any red seeds.”

“This crop was desiccated on 26th July. Usually our rape crops have a birthday, but last year it was ready early and was combined on the 14th August- and the rest as they say is now in the YEN records!”

David was Arable Innovator of the Year in the 2018 British Farming Awards, Agriscot Scottish Arable Farmer of the Year finalist in 2018 and Scottish Rural Awards (Agriculture) finalist in 2019, Farmers Weekly Arable Farmer of the Year finalist 2019 and Scottish Land & Estates award winner 2019.

2016 saw Mr Fuller Shapcott take second highest potential yield prize in ADAS’s Yield Enhancement Network (YEN) wheat competition, achieving over 60% of the crop’s calculated potential yield.

This was a step up from 2015 when a yield of 14.2t/ha gave him the bronze potential yield award in a bumper harvest year when just across the border Northumberland grower Rod Smith broke the world record with a yield of 16.52t/ha.

Surprise Success for Scottish Oilseed Rape CropThe Lawson brothers, Mark, Philip and Ben, farm in Newton Stewart in Dumfries and Galloway – tucked into the bay just before Stranraer – generally not an area renowned for producing award winning oilseed rape crops. However Mark’s crop of oilseed rape won a silver award in the 2022 YEN awards with his crop achieving 84% of its potential yielding 7.39t/ha.

“When the awards were announced we couldn’t believe it. It was really unexpected, we never expected anything like that from a crop on this farm!” says a delighted Mark.

“It’s really wet here – and the soils are not the best- they tend to run to shallow stoney – which although gives us some reprieve from the rainfall as the water runs through it – also means we don’t have lovely, deep soils for the crop to sit its roots down into – not the best for highest yielding crops.”

Airlies farm stands out amongst its neighbours as it’s a purely arable rotation, bar some bed and breakfast cattle, in an area that traditionally is all livestock farming.

The Lawson’s bought, what was then a purely a livestock farm in 1989. However increased costs to transport bought in feed for the herd meant they started to grow their own. Over the years, the arable side has taken over and now have a rotation based on wheat, barley and oilseed rape. Grass is grown for silage and the rougher pastures support sheep.

“Our farm average oilseed rape yields can be around 3.7 t/ha but if we can push this to 4.2-4.4t/ha we are happy with that.”

“It hadn’t really occurred to us to enter YEN. We didn’t think we had much hope of winning anything and were unsure what we would gain from the experience, but a conversation with our seed advisor, Douglas Bonn of Nickerson Seeds convinced us to enter.

Mark Lawson and Douglas Bonn

“We had a field of Acacia oilseed rape that looked good and showed promise, so on discussion with Douglas we were persuaded to enter part of that field.”

“We used to grow variety Anastasia, so it made sense to move onto Acacia.”

Bred by Limagrain UK, Acacia is the most popular conventional variety in the country with proven strong autumn growth and good spring vigour, solid disease resistance and short, stiff straw, combined with a high oil content and yield.

“Whilst there has been a tendency to move into hybrids generally, many growers have found that Acacia delivers the vigour and consistency of performance that they are looking for,” explains Douglas.

He explains that Mark has always been interested in improving what he does on farm, so when the crop showed so much promise it made sense to enter it into the YEN for the valuable feedback gained from the judging.

Award winning cropping

“All in all it was a pretty easy season on the crop, says Mr Lawson.” Autumn 2021 had been really kind – all the crops drilled in good time. With the high levels of rainfall here our biggest challenge is getting the crops in the ground in good time.”

“Following winter barley, the oilseed rape was drilled into a nice dry seed bed. We min-till using a Simba Xpress which creates a good tilth for the seed. Seed rate was 3.55kg/ha – with an aim for an established plant count of 24 plants/m2.”

With regards to agronomy of the crop, Richard Bray, agronomist with Agrovista based in south-west Scotland says “It was a season when everything came together.”

“The crop came out of the winter well, so we included growth regulation at stem extension as we wanted to avoid a lodged or leaning crop that would not mature evenly or maximise pod fill. In with this, we also applied a broad spectrum foliar feed,” he says

“Tissue analysis highlighted the crop was still short of boron. So we addressed this at the early flowering stage with a 4-way mix containing boron, a carboxamide and triazolinthione fungicide for sclerotinia, a bio- stimulant to boost yield by increasing the numbers of seed per plant and an adjuvant to aid uptake.”

Mr Bray points out that as the flowering period can last many weeks this far north, a second mix at mid-flowering was applied but with the addition of a crop enhancer to increase chlorophyll production and maximise green leaf area.

“As far as weeds and diseases go, we can have issues with sterile brome but the oilseed rape does allow us to clean that up reasonably well. Light leaf spot can be an issue but again we were able to keep on top of that in the spray programme.

“It really is very rewarding for the Lawson’s to achieve this success and do so well against the more recognised arable areas of the east,” says Mr Bray.

Harvest promise

Mark explains how exciting it was when the combine started working in the field of Acacia. “We started harvesting on the 5th August in a neighbouring field and that looked pretty good, so we were very hopeful when we moved into the YEN crop – and in fact we struggled to get it all into the trailer- so we knew we were onto some high yields.”

Acacia

“Entering YEN has been a really positive experience, we have learnt so much and will use what we can in this year’s crop. We will definitely enter YEN again there is always more to learn and build on from last year. Our objective is to be able to produce this level of yield consistently, year on year.”

Why did OSR yield so well in 2022?

A decade of YEN research shows that while light and water availability remain critical limiting factors to yield potential, successful crops are those with optimal biological growth to convert the energy available into grain.

Maximising biomass puts crops in a prime position to convert sunlight into yield, even if that yield potential is limited by factors beyond your control. So how did 2022 fare?

Looking at 2022 season:

- Analysis by YEN of historic weather patterns and OSR yields have revealed that high yielding seasons are associated with a warm October, dry December, warm minimum March temperatures, dry/sunny April and a wet/cool May.

- The 2021-22 season was characterized by a warm October, a dry December and winter, average March temperature, a dry sunny April and an average rainfall and warm May.

- The dry spring helped to restrict canopy growth which will have helped optimize canopy size at flowering for good seed set and reduce the risk of lodging.

- The sunny conditions in April will have helped crops to set many pods. Rainfall in May will have been particularly beneficial for crops suffering from the earlier dry spring conditions, but the dull conditions might have restricted the number of seeds set per pod.

On the whole, conditions were conducive for setting high seed numbers and hence higher potential yields

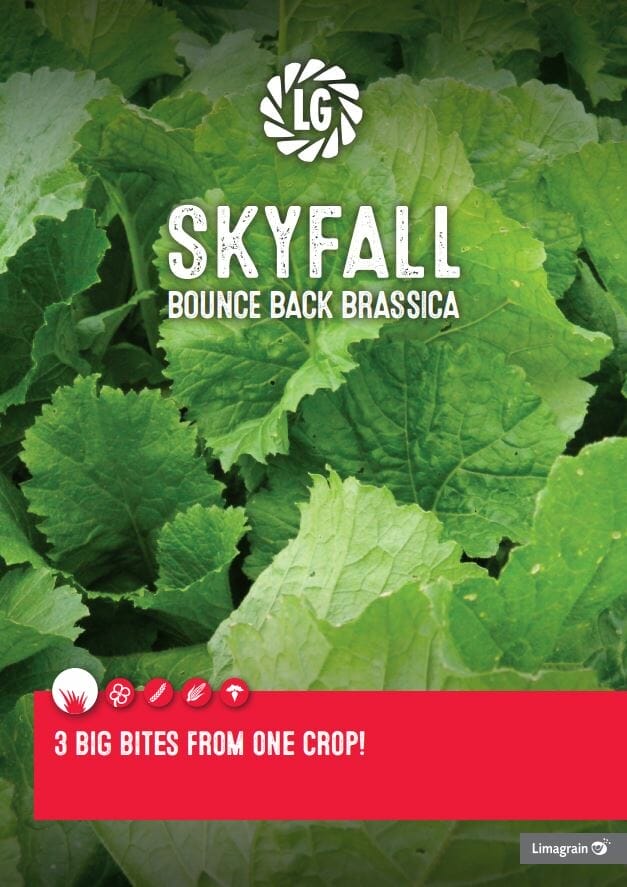

Skyfall – forage of choice for Cornish sheep & cattleKeen to try new crops, sheep and beef farmer Philip Sims was interested to see how Limagrain UK’s relatively new bounce back brassica Skyfall performed on the farm and what sort of feed it provided.

Philip Sims, his wife Susan and son Robert run a flock of Texel cross sheep and a 35-cow suckler herd on the 170-acre unit at St Wenn, Bodmin in Cornwall.

Land reaches 213m (700’) above sea level. Most of the land grows good quality forages, predominantly grass for silage and hay, and also grazing, plus maize and fodder crops.

Land reaches 213m (700’) above sea level. Most of the land grows good quality forages, predominantly grass for silage and hay, and also grazing, plus maize and fodder crops.

Philip, who moved to the farm in 1956 with his parents, looks to grow as much feed for the livestock on the farm and reduce their reliance on bought in concentrates.

So extending the grazing period and the portfolio of forages is always on the cards here. And introducing a range of forages places less reliance on grass, should it be a very hot, dry summer and grass growth stalls.

Keen to try new crops, Philip was interested to see how Limagrain’s relatively new bounce back brassica Skyfall performed on the farm and what sort of feed it provided. So, in April 2021, he sowed three hectares (about seven acres) of seed into a maize stubble. Nitrogen fertiliser was applied at a rate of 200kg a hectare.

Six weeks later, at the end of May, 100% of the crop had germinated and the plants were 15cm (6”) tall and fit for grazing.

“We opened the Skyfall crop to a group of 60 ewe lambs,” says Philip. “The crop was part of an eight hectare (20 acre) field. What surprised me so much was that the sheep always headed for the Skyfall out of preference. They did very well on it.”

Once the crop was grazed off after about two weeks, it was shut up and left to re-grow – or ‘bounce-back’. True to its word, the crop was ready for grazing again a few weeks later.

Once the crop was grazed off after about two weeks, it was shut up and left to re-grow – or ‘bounce-back’. True to its word, the crop was ready for grazing again a few weeks later.

“We repeated this a few times and in June we grazed the cattle on it,” adds Philip. “They also loved it – are loving it – it must be some sweetness in the leaves? But whatever it is, Skyfall is very palatable to both sheep and cattle, and they did well on it.”

The crop was then followed with an autumn grass reseed.

“Limagrain’s adviser Graham Parnell suggested we might want to add a fertilizer to the crop after a few rounds of grazing,” added Philip. “But we were happy enough with its natural growth. It just doesn’t stop growing. It’s a win-win really.”

So pleased with the performance of Skyfall, Philip is growing more. “It certainly provides a good fresh bite in spring and summer and adds to our grazing forages, taking the pressure off grass.”

BOUNCE BACK BRASSICA BENEFITS – SKYFALL

• High protein forage

• Fast-growing – normal 10 weeks from sowing to grazing, but less in this case

• Leafy and palatable grazing crop for cattle and sheep

• Produces between 30 and 35 tonnes/ha

• Deep rooting so withstands dry conditions

• Regrowth potential – bounces back after first round of grazing and provides a second crop.

• Break crop – short-circuits weeds and pest problems in grassland

More information

Download the LG Skyfall bounceback brassica growers guide below

Skyfall – the bounce back brassica that keeps on growingLimagrain UK’s bounce back brassica Skyfall is the perfect answer to ensuring that a highly nutritious leafy forage crop is available for grazing sheep and cattle in summer through to autumn.

Sown between May and July, it will be ready for grazing in 12 to 14 weeks. And after the first round of grazing, it can be closed up for six to eight weeks while it grows back, ready for grazing again later in the season.

“Its deep narrow roots allow it to thrive in drier soils through summer,” says Limagrain’s forage crop manager John Spence. “This, and the crop’s exceptional vigour supports regrowth and a second grazing crop. In field trials Skyfall produced between 30 and 35 tonnes/ha of a palatable soft-leaved forage where the crop was sown in July.”

“Its deep narrow roots allow it to thrive in drier soils through summer,” says Limagrain’s forage crop manager John Spence. “This, and the crop’s exceptional vigour supports regrowth and a second grazing crop. In field trials Skyfall produced between 30 and 35 tonnes/ha of a palatable soft-leaved forage where the crop was sown in July.”

Skyfall is an ideal break crop too before a grass reseed or in a mixed arable rotation.

Sheep farmer and contractor Tim Cains was an early pioneer, sowing a crop in the first season that Limagrain introduced it. He used it for his lambs, and they devoured it first time round, and second time round six weeks later when he finished them off the crop at 40kg liveweight.

Tim Cains from Bridgnorth runs a 500-ewe flock – 300 Welsh mules and 200 Scottish Blackface hill ewes. Lambing starts in late March and lambs are reared for finishing from September.

“This puts a lot of pressure on our grassland,” says Tim, who combines his sheep enterprise with a mobile sheep dipping business.

“We lamb the mules indoors then turn the ewes and lambs out onto grassland. We’ve 130 acres of grassland for the sheep, and finish around 500 lambs, keeping 120 ewe lambs for replacements.”

Lambs are weaned from the second week of July, and in 2020 Tim moved them straight on to the bounce back brassica Skyfall. The crop’s proven track record of great growth potential through summer and the ability to ‘bounce back’ appealed to him.

“We wanted to ease the pressure on the grazed grass and reduce reliance on bought in feed, should the grass be in short supply later in summer,” says Tim.

“We got 24kg of seed – treated with Start-Up to promote germination and even establishment, for our 13-acre ley (5.3ha). I drilled it in early May and by the time I moved 300 lambs on to it at the end of July the leaves were so big we couldn’t see the lambs. There’s not much bulb, but plenty of leaf.”

And it went down a treat. “The lambs loved it, and devoured the crop in three weeks, grazing it right down. We moved them off in mid-August onto a red clover sward and supplemented their diet with some creep.

“I then waited to see if the crop did what it was meant to do and re-grow enough for another grazing. I have to admit to being a bit skeptical. We’d only had three weeks grazing off the crop so far, so its value depended on a re-growth. We needed another three weeks of grazing to make it viable; to justify growing it,” he adds.

It wasn’t a very long wait before Tim knew this crop ‘had legs’. Within 10 days, regrowth was about 30cm. “I took photos of the crop in mid-August as I couldn’t believe the speed of the regrowth. It was exceptional.”

About 270 lambs were moved back on to the Skyfall at the beginning of October and Tim pulled finished lambs off the crop at around 40kg liveweight. “They sold well – the market was fairly strong last autumn. All bar 56 of the smallest lambs were sold in October; something we’ve never achieved in the past. We’re normally aiming for the Christmas market, and don’t really ‘push’ the lambs. We didn’t have to with this crop, but we got to finishing weights much earlier.

About 270 lambs were moved back on to the Skyfall at the beginning of October and Tim pulled finished lambs off the crop at around 40kg liveweight. “They sold well – the market was fairly strong last autumn. All bar 56 of the smallest lambs were sold in October; something we’ve never achieved in the past. We’re normally aiming for the Christmas market, and don’t really ‘push’ the lambs. We didn’t have to with this crop, but we got to finishing weights much earlier.

He admits that this sort of bounce back brassica is a new one for him. “But it worked really well. Lambs reached finishing weights more cost-effectively, and it gave the grass a break too.

“And I gave the crop a fair test as we used some fairly unproductive permanent pasture to grow it. It wasn’t very fertile ground and maybe not the best choice to try out this new crop, but it performed far better than I expected.”

Plans were to follow the brassica with a herbal ley in autumn but this was put back to spring 2021 to make the most of the regrowth. “I’d still got 56 lambs grazing it in late November.

“Maximising home-grown forage production is crucial and fine tuning the cropping rotation will improve output,” says Tim. “We grow 20 acres of turnips for over-wintering ewes and high energy fodder beet for later finishing lambs.

“We also need to up the grassland management but establishing new leys is challenging here as the stone in the soil makes ploughing very difficult. So being able to burn off grass and drill a brassica in directly then burning off again before planting a herbal ley saves time and machinery. It also helps clean the old grasses out ready for the new ley.

“A rotation of brassica, grass and roots seems to work well for us. And the regrowth track record of this brassica means I will aim to sow it earlier this year – I might get even more from it through summer and autumn!”

-

crop facts: SKYFALL BOUNCE BACK BRASSICA

High protein forage

Fast-growing – 10 to 12 weeks from sowing to grazing

Leafy and palatable grazing crop for cattle and sheep

Produces between 30 and 35 tonnes/ha

Deep rooting so withstands dry conditions

Regrowth potential – bounces back after first round of grazing and provides a second crop.

Break crop – short-circuits weeds and pest problems in grassland

More information

Download the LG Skyfall bounceback brassica growers guide below

Crusoe delivers for Gold award winning growerAfter scooping top spot in the 2022 Yield Enhancement Network (YEN) Milling Quality Awards, Crusoe has once again proven its reliability for Norfolk farmer Chris Eglington.

Chris Eglington

More than one-third (150 ha) of the 400 ha farm near Dereham is down to Group 1 milling wheats, divided evenly between Crusoe in the first wheat slot after peas or oilseed rape, and Skyfall as a second wheat.

“We’ve been growing Crusoe for at least eight seasons and it is a very reliable variety,” Mr Eglington says. “It’s not necessarily the highest yielding, but it performs every year.”

This performance was clearly demonstrated last harvest, when his YEN entry won Gold in the YEN Milling Quality Awards, with a protein content of 14.4%, specific weight at 80.7 kg/hl, and Hagberg of 355 seconds. This bucked the trend in a season characterised by high specific weights and Hagberg falling numbers, but generally lower protein content.

Mr Eglington acknowledges optimising yield and achieving full milling specification is a fine balancing act, but says Crusoe has generally met the grade every year he has grown it.

His YEN-winning crop was managed no differently to other milling wheats on the farm, which has operated a controlled traffic system across the entire area for the past decade.

For the 2022 YEN crop, grown on a good medium loam field, the preceding Aspire oilseed rape stubble was allowed to green-up for as long as possible, before cultivating with an 8-metre Vaderstad Carrier in early September. Wheat was then drilled within a couple of days, using the farm’s 8-metre Vaderstad Rapid, rolled, and a residual herbicide applied.

“We use variable seed rates, based primarily on the soil’s clay content. There are 13 different soil types on the farm, from sand to strong clay, and in some cases the subsoil is different to the topsoil.

“Generally, the lighter the land, the lower the seed rate, whereas on the heavier land we’ll increase rates, as it is usually harder to create the optimum seedbed. Having said that, conditions were so good last autumn, some of the heavier land established better than the lighter ground.”

Little and often nutrition

After many years of growing milling wheats, Mr Eglington recognises the importance of optimising crop nutrition to achieve both yield and the quality required by end users.

Variable rate potash, lime (where required) and nitrogen applications are used across the farm, and he has worked closely with grain buyer Camgrain, and in the past with Sainsbury’s, to optimise nitrogen inputs and protein.

“Although there’s a lot of pressure to reduce nitrogen use on farms, there’s no escaping the fact that if you want to get a good milling wheat crop with high yield and high protein, unfortunately there is no other option than to make sure the crop has enough nitrogen. Being a few kilos under could take away the premium and be a big money loser.”

He favours a “little and often” approach, based on his experience of growing milling wheats, and in-season crop monitoring to fine-tune requirements.

Although the preceding crop can affect residual nitrogen levels in the soil, given the uncertainty over how much will be available and taken up by the plant, Mr Eglington prefers to use regular tissue testing as a means of adjusting nitrogen programmes to crop need.

“We haven’t really done much soil testing, but do use the Yara N-Tester to test what’s in the plant tissue, and then the N-Sensor to apply nitrogen where it’s needed, and less where it’s not, so you end up with a very even crop.”

On average, first wheats typically receive a total of 280 kg N/ha, with second wheats getting an additional 10-15 kg N/ha, due to the lower residual nitrogen after the preceding wheat crop.

Nitrogen is normally applied as four splits of solid granular fertiliser, but will sometimes be supplemented with a small amount of liquid urea towards the end of the season (June) to help build grain protein if required.

Keeping crops clean

A standard four-spray fungicide programme is used across all of Mr Eglington’s wheats, from T0 through to T3.

“We don’t cut corners in terms of timing. It would be very unusual for us to miss out one of the main fungicide sprays, but we will alter products according to the weather and disease pressure at the time. AHDB benchmarking data shows we generally spend slightly less than average on fungicides, but spray slightly more frequently.

“Again, it’s a little and often approach. Fire-fighting disease is a lot more difficult than going out there and preventing it in the first place.”

Disease-wise, he says Crusoe is a predictable variety with no significant problems. “We know brown rust can be an issue later in the season, so we treat crops accordingly to manage that risk.

Fuel from fodder beet supports cow performance“We have tried other milling varieties in the past, but and have come back to Crusoe because it is a reliable variety,” he concludes.

Pembrokeshire dairy farmer Roger James relies on a high energy diet in early lactation to keep his 300-cow cross bred dairy herd in good body condition and able to support milk production and high fertility levels in a trouble-free fashion.

He gets this from a combination of breeding and nutrition.

Roger says his medium-sized strong cows are ideal – a cross of Montbeliarde, Norwegian Red and British Friesian genetics. “And if we feed them properly, they produce good quality milk, stay fit and get back in calf easily.”

The diet is based on a TMR comprising grass and wholecrop silage and fodder beet – all home-grown forages – plus molasses and a blend, as well as a rumen buffer, vitamins and minerals. This supports average yields in this NMR-recorded herd of 8,000 litres at 4.35% fat and 3.50% protein on twice-a-day milking.

“The fodder beet gives our cows plenty of energy and that, in turn, results in good fertility,” says Roger.

“We target, and usually achieve, a 365-day average calving interval. Getting cows back in calf is the cornerstone of our management system here. We’re mainly autumn calving and look to calve 240 cows in an eight-week period from October.”

Fodder beet is introduced to the ration early in December at a rate of 6kg per cow per day, increasing to 8kg per head by the end of the month to get the energy up, ahead of starting to AI cows from the beginning of January.

Around 3.6 hectares of fodder beet is sown in April and provides a break crop for wholecrop wheat. “The land is free-draining, and the fodder beet grows really well, whatever the season throws at it,” he says. “We lift about 320 tonne of fodder beet each year, and yield doesn’t vary much from year to year.” Average yield is about 90t/ha.

He says that during the decade of growing the crop, he’s never had a bad harvest. “In fact, we’ve had some of our best yields when it’s been really dry and hot, such as in 2018 and in 2022. I think the extra warmth in the soil, when it did eventually rain, meant the beet grew like mad and more than made up for lost time.”

Fodder beet grown at Moat Grange, just south of the Preseli hills in the heart of Pembrokeshire, is lifted in early November and stored in a clamp, before being washed, chopped and added to the TMR.

“We feed it in the TMR even after the cows are turned out in mid-March. They’re given a buffer to support yields and fed concentrate in the parlour until milk eases off and they’re approaching drying off.

“The fodder beet keeps well, until mid-April when temperatures warm up and it starts to go soft. But we aim to have finished feeding it all by then.”

Roger is discerning about the variety he grows and takes advice from his Wynnstay adviser Laurence Couzens.

“We’ve opted for Robbos for the past few years, and I’m pleased with it. It offers a high dry matter yield and feed value. And the smooth skin, and the fact that it’s not too deep rooted, means it lifts out clean and easily, making it easier to wash.

“I know I don’t necessarily need to wash it, and many growers don’t, but I prefer to reduce any risk of soil contamination,” says Roger.

He farms the 174-hectare unit, which has been in the family for more than 100 years, in partnership with his father Robert and brother Simon.

Roger manages the dairy herd and followers with the help of a cowman and two full-time staff. His partner Angharad is also developing a gelato business – Llaeth Preseli Milk and Gelato – using milk from the herd.

“Milk quality from healthy and productive cows is important to us,” he adds. “We sell pasteurised milk and handmade gelato directly from the farm. The milk is sold through a vending machine, and the gelato is served from a trailer in our ‘gelato garden’. Both these ventures are brand new and going well so far. Most of the herd’s milk is sold to First Milk and used for making cheddar cheese.

“Milk quality from healthy and productive cows is important to us,” he adds. “We sell pasteurised milk and handmade gelato directly from the farm. The milk is sold through a vending machine, and the gelato is served from a trailer in our ‘gelato garden’. Both these ventures are brand new and going well so far. Most of the herd’s milk is sold to First Milk and used for making cheddar cheese.

“We’re aiming to get the best from our unit and our cows. Our home- grown forage is vital. First cut is taken in mid-May – a little later than some would take it, but it means there’s more fibre in the silage and this balances well with the wholecrop. The fodder beet is the icing on the cake. Cows keep well on this, and production, health and fertility are good. So is our gelato!””

KEY FACTS ON FODDER BEET

- Sown in March – April

Can be part of a grass rotation or an alternative to spring cereal crops to provide livestock feed and break the pest and disease cycle

- Harvest flexibility

Crop can be lifted from late October until March. Little loss in feed value, if any, is typically seen in later harvested crops.

- High energy feed provides high feed value

Average ME 12.5-13MJ/kg DM, 162,500 – 202,500MJ/ha with more recent varieties producing well above this level.

- Choice of variety to suit the system

Consider root depth, disease resistance, bolting score

There are no recommended lists for fodder beet varieties, but Limagrain UK’s annual fodder beet trial results are available to all growers and farmers.

more information

Learn more about Robbos fodder beet here or contact your usual seed merchant for availability

The latest UK trial results data on fodder beet (including Fosyma) can be downloaded here

LG GatePost Newsletter – Feb 2023

The February 2023 issue of LG GatePost is now available to download.

This edition features articles about our exciting new Wheat, Winter Barley and Oilseed Rape varieties that are taking leading positions across the 2023/24 AHDB Recommended List.

You can read about how moving to direct drilling of LG Diablo Spring Barley has proven successful for Berwickshire grower, Neil White and watch our Spring Barley agronomy series of videos that give you all the technical know-how to successfully grow your Spring Barley crop.

There is also information about our upcoming Trials Events, and online Technical Webinar.