Winter barley variety LG Capitol has withstood one of the wettest seasons on record as well as any winter wheat and looks full of promise heading towards harvest 2024, says Shropshire farmer & contractor, Rob Bebbington.

Fieldfare Farmers covers some 365 ha (900 acres) for a range of clients across Cheshire, Shropshire, and north Wales. It has a varied rotation, split roughly 50:50 between autumn cereals and spring cropping, including potatoes, forage maize, oilseed rape, winter wheat and winter barley.

Winter barley is grown primarily as an early entry for oilseed rape, and this year, Mr Bebbington’s whole barley area (28 ha) is down to LG Capitol, grown for the first time on the recommendation of seed supplier and grain buyer, Wynnstay.

“Historically, 20 years ago, winter barley always looked a bit disappointing after a wet, cold winter, whereas with the improvements in genetics we’ve seen in recent years, now it almost seems to withstand the conditions as well as any winter wheat,” says Mr Bebbington.

“Indeed, despite one of the wettest years we’ve ever had, LG Capitol has stood up to the wet autumn and spring, and looks incredible! I can’t wait to see how it performs going into the shed this harvest.”

This year’s LG Capitol was sown on 26 September at a seed rate of 165 kg/ha, after forage maize. Land was ploughed, power harrowed and drilled in good time last autumn, allowing crops just enough time to establish before the winter set in, he says.

In total, the LG Capitol received 165 kg N/ha (applied as 26N 31SO3 and granulated urea), two fungicides based on bixafen, Fluopyram + prothioconazole and fluxapyroxad + Mefentrifluconazole, plus a mepiquat-based growth regulator, and foliar manganese.

Mr Bebbington says winter barley yields typically average around 7.6-8 t/ha (3.1-3.2 t/acre), but looking at the condition of the LG Capitol approaching harvest, he is cautiously optimistic that this year’s crop will at least match, if not exceed, that level.

The crop will be followed by oilseed rape. “We still like growing oilseed rape; it fits in well with our rotation and gives us a good spread of cropping, with winter barley providing an excellent early entry. Fingers crossed we haven’t suffered too badly with cabbage stem flea beetle.”

Looking ahead to the coming autumn, Mr Bebbington says end user requirements remain a key driver of varietal choices, so will again influence final decisions.

“But at the same time, we like LG Capitol, and don’t feel a need to change from it.”

LG Capitol

- –> Highest yielding 2-row winter barley for the east & north

- –> Yield comparable with hybrid varieties

- –> Strong disease resistance – notably brown rust, Rhynchosporium & mildew

- –> Good specific weight & screenings

From early to late drilling, ploughed land to min-tilled, and high to low soil fertility, Fife farmer & contractor, Zander Hughes, faces almost every possible cropping scenario across the 320 ha (800 acres) he farms for a range of clients.

Zander Hughes

Such variability represents a stern test for any variety, but for Mr Hughes, LG Skyscraper continues to be the stand-out performer in terms of its consistent yield and quality across multiple seasons, and flexibility to go into a range of drilling situations.

Having grown LG Skyscraper since its launch five years ago, the variety once again accounts for his entire winter wheat area, with around 130 ha in the ground for harvest 2024, up from 81 ha last season, due to rotational shifts and a slight reduction in spring barley area. Most is sown as a first wheat after potatoes, vegetables, grass, or spring barley.

“We’ve never had any problems with LG Skyscraper; we really like it as a variety. To this day, LG Skyscraper remains the variety that produced the biggest yield I’ve ever grown, at 14.5 t/ha in the year we first tried it.”

Although last year’s crop did not quite reach that level, he says it still performed really well, averaging 10.5-10.75 t/ha across the whole wheat area, with big, bold grains, good quality, and plenty of straw that stood well.

That performance came despite relatively high disease pressure last season, and challenging conditions that meant the first T0 fungicide, plus growth regulator, could not be applied, he notes.

“That did put slightly more pressure on the T1 and T2 growth regulators in high fertility situations, but despite this, crops generally still stood really well.”

Looking good in a tough year

As for this year’s crop, Mr Hughes says the vast majority was drilled into good conditions, despite tricky autumn weather that stretched the drilling window from 1 September to mid-November. Some fields were ploughed, while others were min-tilled, although decisions are very much taken on a field-by-field basis, depending on soil conditions and previous cropping, he notes.

LG Skyscraper has a fairly vigorous growth habit once it germinates, so Mr Hughes has no fear of sowing it later, as he might with some other varieties.

As always, seed rates were adjusted according to drilling date and conditions, ranging from 375 seeds/m2 at the lowest, up to 525 seeds/m2 in the most challenging situations last autumn.

“At the moment, there aren’t really any obvious differences between the early and late-sown crops. We’ve found that standing water on some fields – which is a new thing for us this year – has had more of an effect than drilling date.”

With most crops around growth stage 31 (T1) at the time of writing, Mr Hughes says generally the LG Skyscraper all looks well, with no obvious issues, despite ideal conditions for Septoria and yellow rust development over much of the season so far.

Given higher disease risk, robust SDHI and triazole-based T1 and T2 fungicides will be used to protect the important yield-building leaves through the remainder of the growing season, and maximise crop potential. This will build on the prothioconazole-based T0 applied earlier this spring, accompanied by trinexapac-ethyl and chlormequat growth regulators, and trace elements.

“Growth stages are slightly all over the place at the moment, even within the same field, so we’re hoping the T0 growth regulator will reduce the apical dominance of the main stems a bit, as they’re a lot further on than the tillers at this stage. We’ll also apply another growth regulator at T1, although decisions are taken on a field-by-field basis.”

Nitrogen is usually applied in three doses, but this year Mr Hughes has favoured more of a “little and often” approach, based on four applications of granular fertiliser, roughly in a 30-40-20-10% split, to reduce any potential risks of field losses due to the weather. Total application generally averages around 210 kg/ha, although this ranges from 180 kg/ha to 240 kg/ha depending on soil levels and crop potential.

Sticking with LG Skyscraper

Looking ahead to next season, Mr Hughes plans to continue growing LG Skyscraper, although is also going to try Limagrain UK’s new hard Group 4 variety, LG Beowulf, which joined the AHDB Recommended List this year as the highest yielding winter wheat.

LG Skyscraper is just one of 16 varieties featuring in a Limagrain UK variety demonstration that Mr Hughes is hosting for the first time this season.

“The demonstration is being held on one of our contract farms that hasn’t grown wheat for around 15 years. My initial plan was to go with LG Skyscraper on this farm, because it’s one we like and has done well for us, but there was some debate as to what variety would best suit the farm, hence hosting the trial here.”

As well as a range of Limagrain UK and competitor varieties, the demonstration is also looking at the impact of different seed rates on four Limagrain wheats, sown at half, three-quarters, 100%, and 125% of the standard seed rate.

LG Skyscraper

–> Soft Group 4 wheat

–> First listed on the RL in 2019

–> OWBM resistance

–> Good yellow rust resistance (7)/ Septoria requires monitoring

–> Consistent yield and quality performance over multiple years

–> Flexibility for a range of rotational positions (1st or 2nd wheat), sowing dates, and soil types

–> Good grain quality – specific weight (77.1 kg/hl)

–> End market flexibility – feed/ distilling/ biscuit grists

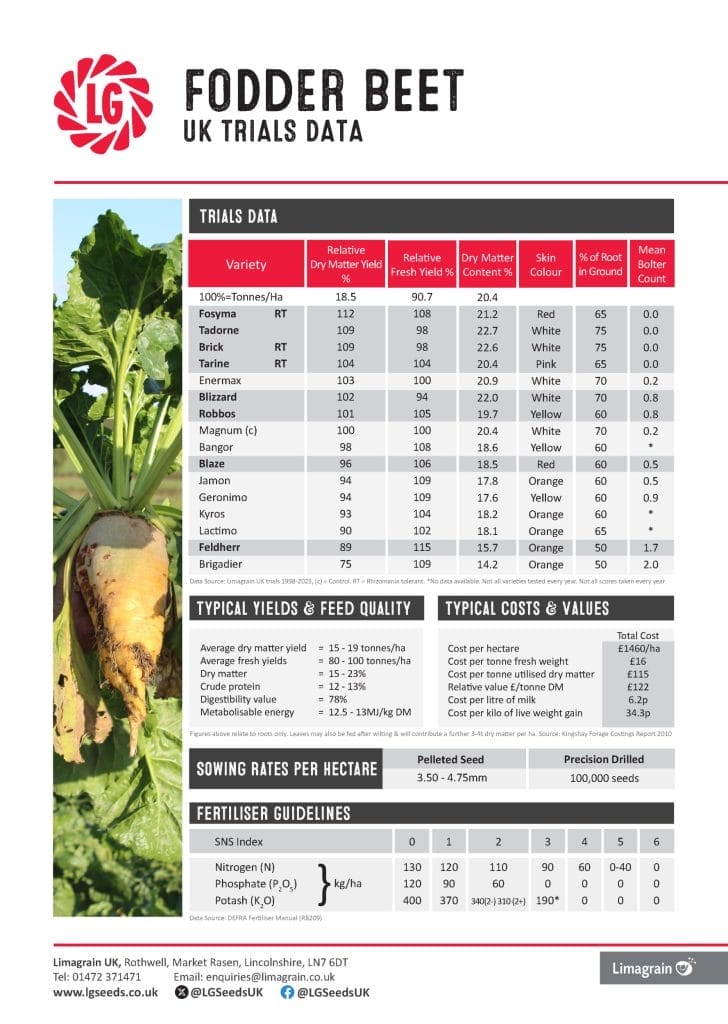

Successful foray into fodder beet for East Lothian farmerThe challenges of dry summers and increasing input prices have tempted one East Lothian beef farmer into trying out fodder beet for finishing his beef cattle.

And Anderson Waddell has no regrets, and for now, he’s committed to a crop each year. In May 2023, his contractors sowed six hectares of plant breeder Limagrain’s Robbos fodder beet and lifted about 120 tonnes per hectare fresh weight (50t/acre) of the crop in November. He’s recorded good intakes of this high energy feed and found an improvement in the finished cattle.

Anderson runs the 150-hectare beef and arable family farm at Pencaitland, East Lothian, 14 miles southeast of Edinburgh. He buys about 90 six-month old male calves, mainly from one farmer, between October and December each year. Most are pure Charolais, and the rest – about 25% – are Limousin.

Anderson runs the 150-hectare beef and arable family farm at Pencaitland, East Lothian, 14 miles southeast of Edinburgh. He buys about 90 six-month old male calves, mainly from one farmer, between October and December each year. Most are pure Charolais, and the rest – about 25% – are Limousin.

These calves go out to grass the following spring at around 300kg liveweight and are then housed from 430kg to finishing weights of 650kg to 700kg.

Indoors, cattle get a diet of grass silage and homegrown barley in troughs which this year has been mixed with chopped fodder beet.

“By October each year I can have about 280 cattle on the farm, so I need a reliable source of high quality feed,” he says, adding that the dry summers have knocked back silage yields and increasing input prices have affected the cost of growing barley.

“So I was keen to look at alternative home grown feeds to eke out supplies of silage and reduce my reliance on feed barley. I am to be self-sufficient in feed supplies.”

Many friends in the area grow fodder beet so Anderson asked around for some tips and took the recommendation from his seed merchant Dods of Haddington.

“The reliability and consistency of fodder beet yields, and its feed value made it an attractive option, and the variety Robbos, which is tried and tested was recommended and a lot around here grow it,” he adds. “So it seemed like a good option to start with.”

The crop was sown into prepared land following barley. Anderson applied plenty of dung on the stubble prior to ploughing and preparing the seed bad.

“Input costs after sowing were relatively small – just three weed treatments were applied between May and June. Establishment was good and despite some dry conditions, the crop kept growing.”

His contractor lifted the crop in November – which Anderson admits was a bit late in view of the wet conditions. “But it yielded well and it’s certainly taken pressure off the silage and barley. Cattle have grown well and they’re killing out better.”

He wants to improve the chopping equipment – last winter he used a Ritchie Root bucket feeder, which was not ideal. “I’ve still a bit to learn with growing and feeding fodder beet but it’s just what I needed in the diet and it’s cost-effective,” he adds.

“And I also have plenty of organic matter on the field to promote soil health ahead of the next crop of spring barley that will be drilled in May. So, fodder beet is giving me just what I wanted from a forage crop – it’s a win-win for now.”

Find out more about Robbos fodder beet here and download our latest UK trial results for fodder beet.

Under-sowing Maize Pays DividendsUnder-sowing maize with a hybrid ryegrass and red clover ley has delivered multiple benefits for Cornish dairy farmer Chris Sampson.

With five years of the practice under his belt, and now owning his own inter-row drill, Chris is seeing consistent results, and can list extra forage, increased soil carbon and reduced cultivations amongst the key advantages.

Chris is also eligible for a countryside stewardship payment of £172/ha for what is effectively a cover crop, and all of this is achieved with no detriment to his primary goal of growing a high energy maize crop.

“We grow around 40 acres of maize each year, which makes up about half of the winter forage ration for the milking herd,” Chris explains. “We now routinely under-sow it with a grass and clover mix, with the additional stewardship payment more or less paying for the seed. And, with the extra first cut of grass and clover silage we take the following spring, I’d say the whole exercise pays for itself in the first year.”

Maize was first grown at Metha Farm, near Newquay, around 25 years ago, and is now a mainstay of the milking ration for the 112-cow herd of Holstein Friesians. It is grown in rotation with grass and clover leys, with Chris favouring very early varieties that will produce a mature, high-energy crop in a relatively short growing season.

“We’ve tried growing wholecrop cereals as an alternative to maize, but could never achieve the same level of yield,” he adds. “It’s about maximising the energy production and the best measure of that is megajoules per hectare. With the system we now have, we’re able to exploit the full benefits of high energy maize whilst overcoming any environmental concerns with the crop.”

Grass and clover leys at Metha Farm are typically down for three or four years before that land is used for maize. The policy is usually to take a first cut from the old ley in early May before applying farmyard manure and then preparing the ground to drill maize.

“Our oldest leys are often still quite productive, and we’ll top-dress with nitrogen before taking a first cut,” explains Chris. “Once that crop is off, we have a fairly tight turn around to spray off the aftermath and apply muck before ploughing and preparing a seedbed.

“We find the right time to drill maize is at the end of May, or even the first week of June. We’ve tried drilling earlier but it’s usually better to wait until soil temperatures are higher. Even with the relatively late drilling we usually have a crop that hits the target of ‘knee high by the fourth of July’.”

Chris routinely soil samples all of the land going into maize, with the results determining his fertiliser policy for the crop. He may use up to 50kg/acre of DAP in the seedbed, and low level applications of nitrogen and/or MAP, or may decide there’s no requirement at all, adhering strictly to a principle of only applying what is necessary.

Once weeds have been sprayed off, and with the maize crop up to 12 inches high, Chris goes in with his Weaving inter-row drill, sowing a hybrid ryegrass and red clover mix at a regular seed rate of 14kg/acre.

“It’s a disc drill system and the coulters can be set to drill between the rows of maize,” says Chris. “The mix of hybrid ryegrass and red clover works best for our situation. The establishment is effective, so when the maize comes off in the autumn there’s a wispy crop growing underneath that kicks on very quickly.”

The priority for Chris is a mature crop of maize, so he resists the pressures to cut earlier and waits until the cobs are fit. In 2023 the maize came off on 8th October, with an overall fresh weight yield of around 17.5 tonnes/acre at 35.8% dry matter. With winter feeding well underway, the maize was feeding well, contributing a significant proportion to the total mixed ration for cows averaging 7,500 litres per lactation.

THE BENEFITS OF UNDERSOWING MAIZE

With undersowing becoming increasingly popular, Limagrain Maize Sales Manager, Tim Richmond, explains some of the wide-ranging benefits the practice has to offer.

The principal benefit of undersowing maize with a secondary crop such as ryegrass, clover, or vetch, or a combination of all three, is that it prevents maize stubbles from sitting bare over the winter. This not only reduces nutrient losses and soil erosion caused by run-off, but also makes travelling at harvest and in the subsequent spring easier, with the secondary crop helping to improve and bind soil structure.

The undersown crop also provides a valuable winter or spring crop for livestock to graze as well as providing a home for slurry to be spread in the early spring.

Undersowing also helps to improve soil biology, with worm counts typically 6-7 times higher compared to bare maize stubbles.

The secondary crop will also provide competition against spring germinating weeds, and, if conditions turn too wet to drill the next year’s crop, the land will still have a useful grass crop instead of sitting bare for a second winter.

Maize varieties such as Gema, Dignity, Saxon and Skipper are ideally suited for undersowing as they are early maturing which allows the cover crop to become further established after an early maize harvest, yet still go on to deliver a yield on par with the top performing varieties.

To achieve the best levels of cover crop establishment, the secondary crop should be drilled at a rate of around 15kg/ha (depending on the species and mixture) when the maize is at the 4-5 leaf stage. Avoid drilling the cover crop too late as an overly developed maize canopy will prevent the secondary crop from establishing properly, and ensure a gap of 15cm is left between the cover crop and maize drill rows to prevent any detrimental competition effect on maize yields.

Beef growth rates boosted by high value maizeMaintaining target growth rates in a beef finishing enterprise requires a year-round ration that is well-balanced, high in energy and easily digestible. For Yorkshire farmer Edward Liversidge, based at Primrose Hill Farm, High Catton, the key is to feed a total mixed ration based on high quality maize, with the crop being grown as a fully integrated part of the farm’s arable rotation.

Success comes from the Liversidge family’s years of experience of growing maize and it starts with selecting the right variety for the job.

“First and foremost, we want a variety that is going to perform in our situation, which means it needs to be compatible with our soils and location,” says Edward. “Alongside this, we’re looking for good D-value, ME and starch, because it’s the nutritional value that will drive growth rates.”

York-based agricultural trading company Argrain are the Liversidge’s seed suppliers, with seed specialist Lucy Leedham being trusted to make the right recommendations due to her local knowledge and experience. For the 2023 season, she introduced Limagrain’s first choice early variety Conclusion, highly ranked for ME yield and cell wall digestibility and with the right maturity class for this area.

“Conclusion has performed well in our local trials, and we’ve generally had good feedback on it in our area,” says Lucy. “It’s a very good all-round variety, offering the combination of high yields alongside nutritional quality that this farm demands. It also has the attributes to be grown successfully for grain, in that it is not quick die back and has good standability, which is an option that I know the Liversidges like to have.”

Growing as much as 150 acres of maize each year, the policy at Primrose Hill Farm is to grow two varieties, partly to spread risk, but they do it in a way that ensures a consistent feed is available all year round.

“We tend to split the contractor’s 8-row drill to grow alternating 4-row strips of two different varieties, which – when cut with a 12-row forage harvester – creates a consistent blend in the clamp,” explains Edward. “We’ve combined Conclusion with another high energy variety of similar maturity and achieved an overall fresh weight yield of between 19 and 20 tonnes/acre.

“It’s analysed as we’d hoped, with high starch and digestibility, and is feeding well. It’s exactly what we need to achieve our target growth rates.”

The majority of the maize grown at Primrose Hill Farm is in rotation within the arable acreage, and usually follows an over-winter cover crop that will have been grazed by sheep on tack. The cover crop is geared to meeting the needs of all parties, including the grazier, and would typically include grazing rye and stubble turnips.

Once cover crops have been grazed off, there is plenty of time to spread farmyard manure and prepare a seedbed ahead of maize drilling, which will usually be towards the end of April. One of the routine jobs well ahead of drilling is soil sampling, with the analyses being used to determine any additional fertiliser applications.

“We’re testing our soils in order to create soil nutrient maps, which then allows us to apply phosphate and potassium at variable rates,” adds Edward. “We’ve been doing this for three or four years now, to improve our use of fertilisers and save costs where we can.

“We’re also applying a slow-release liquid nitrogen pre-emergence. This ensures that the crop can draw on nutrient reserves in the soil at the important growth stages, well beyond the point where it’s possible to drive into the crop to top-dress with a granular fertiliser.”

Herbicides are used according to the weed burden in any particular crop, with either one or two applications required.

With nutritional value of the maize the main priority, harvest is determined by cob maturity, and took place in 2023 just before the end of September. It was a bumper crop, and with the clamps at Primrose Hill Farm full, the decision was taken to cut some of the maize for grain.

“We used a local contractor’s machine with a specialist header to harvest some of the maize for crimping,” says Edward. “This worked out really well and, thanks to the Conclusion being suited for taking as either grain or silage, has given us an additional high energy feed for the ration.”

“We used a local contractor’s machine with a specialist header to harvest some of the maize for crimping,” says Edward. “This worked out really well and, thanks to the Conclusion being suited for taking as either grain or silage, has given us an additional high energy feed for the ration.”

The Liversidge’s cattle enterprise involves buying in strong stores, usually British Blue or Angus crosses from dairy herds in the 400 to 500kg range. These are finished on a total mixed ration, to achieve finished liveweights of 670-720kg.

“We aim for a finishing period on the farm of 90-120 days, so we need a ration that is going to drive good growth rates,” concludes Edward. “Good quality maize silage is the basis for the ration, so growing a mature crop is essential. Success with the maize crop means the bigger proportion of what we’re feeding the cattle is homegrown.”

Earlier maize suits rotational approachMaximising the milk produced from homegrown feed is the overriding aim for Cornish dairy farmer Richard Martin, not least because it is his surest route to profit.

With 1,000 high yielding cows on an autumn block calving system at Trethick Farm near Bodmin, Richard Martin relies on maize as the major energy source in the herd’s total mixed ration, with it making up 75% of the forage component during the period of peak lactation.

Achieving consistent yields of the highest quality maize, within a safe harvest window, is imperative, and this is being achieved by managing the crop expertly from seedbed to clamp and by choosing high ranking varieties, now mainly in the ‘very early’ maturity class.

Achieving consistent yields of the highest quality maize, within a safe harvest window, is imperative, and this is being achieved by managing the crop expertly from seedbed to clamp and by choosing high ranking varieties, now mainly in the ‘very early’ maturity class.

“We’re constantly looking at ways to fine tune our maize growing practice, through a combination of better management and ensuring we are using the best available varieties for our purpose,” says Richard.

“Most importantly, we’re growing maize as part of an overall system on the farm, so that it’s fully integrated with everything else that we’re doing.

“We’re rationalising the number of varieties we grow, down from as many as nine in any season to perhaps only three or four in the future. We’re growing 475 acres of maize and have three separate clamps, so ideally, we want three blocks reaching optimum maturity in turn across a manageable harvest period of two to three weeks.”

In 2023, which Richard ranks as one of the better years for growing maize in recent times, harvest started on 20th September and was completed by the first day of October, with crops averaging a fresh weight of approximately 15 tonnes/acre at 30% dry matter and 30% starch. In line with a policy of seeking out the best new varieties, Limagrain’s very early maturating variety, Foxtrot, was recommended to Richard and supplied by Graham Ragg of Mole Valley Farmers, and made a very successful debut on the farm, ‘ticking all the boxes’ for Richard.

“In the last ten years we’ve brought the maize harvest forward by two to three weeks, through the way we manage the crop and by selecting earlier maturing varieties. Very early varieties such as Foxtrot allow us more time, in better conditions, to establish a following crop.”

Maize rarely follows maize at Trethick Farm, but – on the rare occasions that it does – a cover crop is always drilled into the stubble: “Maize usually follows a cereal, or sometimes grass, but if we do have to grow maize after maize then we’ll sow a cover crop like mustard or forage rape,” Richard explains. “The latter gives us the option to graze over winter, but the most important factor is to ensure we avoid the risks of bare soils.”

Whether following a cereal, grass or a cover crop, the policy is always to plough before drilling, and every maize field is soil tested in good time.

“I see maize as a reset for the land, so we check the fertility and pH of every field and apply plenty of organic matter by spreading muck and slurry,” adds Richard. “The soil analysis will determine what fertiliser, if any, we apply. There’s absolutely no point in routinely applying fertiliser if it’s not required, and we’re finding our ground is high in organic matter, with Ps and Ks often up at 4.

apply. There’s absolutely no point in routinely applying fertiliser if it’s not required, and we’re finding our ground is high in organic matter, with Ps and Ks often up at 4.

“By soil sampling and tailoring our soil nutrients accordingly, we’ve cut our use of DAP down the spout by half, with no detriment to crop performance.”

After ploughing, the typical approach is a deep cultivation pass with a Sumo Trio before power harrowing, and then using a drill mounted on a power harrow which ensures the fineness of seedbed that Richard feels is increasingly important.

“In the past two years we’ve moved to using pre-emergence herbicides as a routine, partly because the chemistry available for later spraying is less robust. The pre-ems are more effective with a finer seedbed, we find.

“Whether or not we apply any nitrogen will depend on the season. It’s now more of a tactical application if and when needed, rather than a routine, as we don’t want to waste resources where they aren’t needed.

“With modern varieties we don’t see the need for an eyespot spray, so really it’s then a case of monitoring the crop closely and being ready for harvest.”

Given the high feed rates for maize, Richard is not looking to take the crop too dry, so his target is 30% dry matter and 30% starch. To maximise the feed value of the ensiled crop, he pays close attention to ensuring the crop is properly consolidated in the clamp to optimise fermentation and preservation.

With maize silage providing the bulk of the herd’s energy requirements, cows are yielding a lactation average of 9,000 litres from twice daily milking, with high milk solids of 4.4% butterfat and 3.6% protein. The only feed bought-in to supplement the farm’s homegrown forages and cereals is a protein blend.

With maize silage providing the bulk of the herd’s energy requirements, cows are yielding a lactation average of 9,000 litres from twice daily milking, with high milk solids of 4.4% butterfat and 3.6% protein. The only feed bought-in to supplement the farm’s homegrown forages and cereals is a protein blend.

“We’re not feeding any concentrates in the parlour, and just use one mix across the board for all the milking herd,” says Richard.

“From a peak of 75%, the maize will come down to nearer 50% of the forage ration by the spring. We’re an early turn-out farm, so cows are usually going out to graze by day from mid-to-late February and will receive their TMR at night. By June and July, we’ll have a large part of the herd dry.”

Moving forward, Richard remains focused on continuing to improve production from homegrown feed, and that means becoming even better at growing maize. New varieties with improved digestibility like Foxtrot are an important part of the progress, but so are innovations in management.

“We’ll continue to challenge the way we grow our maize to seek marginal gains,” Richard concludes. “We’re trialling foliar applications of trace elements, for example, and may in future look at things like different seed rates. There’s always room for improvement with what is such an integral part of our system.”

Early maturing maize proves pivotal in rotation

Increasing the acreage of maize in the arable rotation is proving highly successful for Warwickshire farmers Richard and Fred White at their 650ha mixed unit at Swan Farm, near Atherstone.

Increasing the acreage of maize in the arable rotation is proving highly successful for Warwickshire farmers Richard and Fred White at their 650ha mixed unit at Swan Farm, near Atherstone.

Seen firstly as a good alternative break crop to oilseed rape – which has become harder to establish due to the difficulties in controlling flea beetle – maize is now a valuable forage for their beef finishing enterprise as well as an additional cash crop sold to neighbouring dairy and goat farms.

Key to maize fitting into the rotation and also the operational schedule at Swan Farm is the use of a very early maturing variety, with Limagrain’s Gema fitting the bill well for the past two years.

“Harvesting a fully mature maize crop early is important to us for a number of reasons,” explains Richard White. “Firstly, we’re supplying longstanding customers that want the maize for feeding as early as possible, but we also want the fields cleared so that we can prepare the ground for drilling winter wheat.

“This year we harvested 52ha of Gema on 20th September, which was our contractor’s first outing of the season. We weigh representative trailer loads, so we know what we’re selling, and the crop averaged over 20 tonnes/acre fresh weight, which we’re very pleased with.”

Fresh crop samples were taken by Wynnstay’s Ellie Edwards just before harvest, with the analysis coming back at 32% dry matter, 34.4% starch and 11.5 MJ/kg ME, indicating optimum maturity and a high feed value forage. Having sold the seed, Ms. Edwards supported the customer with crop monitoring throughout the growing season and will continue her input through to feed out.

“It was a relatively positive season for growing maize in many areas,” she says, “with rainfall through July and August allowing good summer growth and enabling crops to yield well.”

At Swan Farm, the maize is drilled relatively early, with the 2023 crop going in during the last week of April. The early drilling is at least in part to ensure this job is out of the way before the fodder beet goes in.

“This is another reason why a very early variety like Gema works so well for us,” adds Richard. “Fodder beet is another important break crop in our rotation, and – like the maize – it’s both a cash crop that we sell as well as a valuable feed for our own sheep. By harvesting the maize as early as we do, it’s out of the way before we’re into lifting fodder beet. The two crops work well together in this way.”

Maize, fodder beet and also potatoes now provide the main cereal break crops in the rotation at Swan Farm, which grows up to 400ha of cereals, mainly winter wheat as well as some spring barley and spring oats.

“We’re doing everything we can to stay on top of grass weeds in our wheat, which is why productive break crops as part of a balanced rotation are so important,” says Richard. “We seem to be keeping on top of blackgrass at the moment, but need to be wary of other possible threats, like ryegrass. Staying on top of the problems is key.”

Swan Farm also includes 160ha of low input permanent grassland, which provides grazing for up to 200 cattle and a 450-ewe flock of EasyCare breeding ewes that are lambed in April. The permanent grassland, which is also used to produce hay sold into the equestrian market, helps to underpin a homegrown feed philosophy for both livestock enterprises.

“With the maize silage for finishing beef cattle, fodder beet for fattening lambs, plus our own spring cereals producing rolled barley and oats, we’re avoiding any great reliance on bought in feeds,” adds Richard. “It means our break crops are contributing to the other enterprises on the farm as well as being valuable in the rotation.”

As any effective rotation should, the cropping system at Swan Farm is helping to maintain good soil fertility as well as control weed and disease burdens.

The 2023 crop of Gema maize only had farmyard manure and digestate applied prior to ploughing, with no fertiliser down the spout or applied later. Maize crops were also relatively clean, requiring just one herbicide application during the growing season.

The 2023 crop of Gema maize only had farmyard manure and digestate applied prior to ploughing, with no fertiliser down the spout or applied later. Maize crops were also relatively clean, requiring just one herbicide application during the growing season.

Going forward, as the Whites transition from the current HLS scheme, they are increasing their use of cover crops over the winter. Mixtures comprising mustard, fodder radish, millet and other species are now being grown, providing soil fertility benefits through green manure as well as useful shooting cover.

As they review new environmental scheme options, to work out what is best suited to their farm, one thing that’s fairly certain for the foreseeable future is a continuing commitment to growing very early maturing maize.

Modern fodder beet suits arable rotation and provides essential livestock feed

Brothers Richard and Fred White who run a 650-hectare mixed farm have grown fodder beet as part of their crop rotation for the past 23 years

Brothers Richard and Fred White run a 650-hectare mixed farm, comprising beef, sheep and arable enterprises, in Warwickshire, and they’ve grown fodder beet as part of their crop rotation for the past 23 years, waxing lyrical about its record yields and its part in ticking a lot of boxes in their farming system.

They began growing Limagrain UK variety Fosyma in 2020 after a recommendation from Wynnstay’s Emma Edwards. This high-dry-matter fodder beet variety is pink-skinned and conical-shaped, and it combines a dry matter content of between 20% and 21% with a relatively high proportion of its root (40%) out of the ground, leaving just 60% in the ground.

Essential part of the rotation

“It fits well into our rotation, usually following and preceding winter wheat,” explains Richard. “We also grow forage maize to feed to the 180-head beef herd, as well as oats and barley, which is also rolled and fed to livestock.”

He and Fred thought Fosyma would do well on their Tamworth-based farm, particularly because they lift and feed fodder beet to their Hereford cattle and sheep during the winter.

It’s medium-depth root reduces the risk of soil contamination and offers flexible feeding and end-use options. Their contractor uses root-lifting equipment, typically harvesting the 23 hectares of the crop that they grow each year. Soil contamination has never been an issue for the Whites.

Market options

They store and feed approximately 50% of the fodder beet to their own sheep and cattle. The other half is sold off farm, for between £45 and £50 per tonne. Some has gone to AD plants, and some has also been sold to feed to deer om a nearby estate.

“They really enjoy fodder beet – as do our cattle and sheep. They all do really well on it.”

Producing home-grown feed and forage is a priority for the brothers, but fodder beet is also a useful break crop. “We typically sow is at the end of April, after applying plenty of manure,” explains Richard, adding that the farm comprises a mixture of different soils.

Producing home-grown feed and forage is a priority for the brothers, but fodder beet is also a useful break crop. “We typically sow is at the end of April, after applying plenty of manure,” explains Richard, adding that the farm comprises a mixture of different soils.

“We have heavy, medium and light soils and the crop is sown across them all – we mix it up. And is performs well – we always see good yields.”

Once in the ground, Richard says the fodder beet ‘doesn’t hang about’. “It germinates and grows quickly. We do need to control weeds, to prevent competition, but once well established the crop’s canopy helps to suppress them.”

The crop is typically ready for harvest at the end of September, but they leave it in the ground until lifting in mid-October. As soon as the beet is lifted, they’re ready with the drill and sow winter wheat into the ground. So they’re not leaving the land fallow over winter.

Palatable yields

For the past three years Fosyma has yielded between 30 tonnes and 35 tonnes per acre (75 tonnes and 87 tonnes per hectare). It’s stored outside in a clamp made from straw bales and feeding to outwintered livestock starts when grass growth slows, which is usually at the end of October.

“It’s fed whole, on the ground, to cattle and sheep. We don’t have to chop it. And they love it – there’s no waste.”

Richard adds that as well as adding ‘interest’ to winter rations, fodder beet also supports lamb growth.

The 450-ewe flock lambs in late April, and lambs are finished on the farm’s 400 acres (160-hectares) of permanent pasture and fodder beet during the winter. “We start selling lambs in January, at around 45kg LW,” he says.

The 450-ewe flock lambs in late April, and lambs are finished on the farm’s 400 acres (160-hectares) of permanent pasture and fodder beet during the winter. “We start selling lambs in January, at around 45kg LW,” he says.

Home grown forage saves £

“We don’t buy in any feed or concentrates for the ewes or the lambs – the system is completely forage based.”

The beef enterprise is also predominantly grass based, with only home-grown cereals fed as part of winter ration when cattle are housed. Cattle are finished and sold, at between 24 and 30 months, to local butchers in Atherstone

In 2021, Richard grew a crop that looked very ‘bare’. “The seed went in well, as usual, but were no beet plants and there were no weeds either. It was odd and Limagrain UK’s Brian Copestake came to take a look because I was at a loss as to what had happened.

“He said it was a flea beetle problem and while I was deliberating about re-drilling, the field suddenly sprouted green rows of beet plants. It soon caught up and within weeks we had a field full of strong and healthy beet that as well up to calf level. It bounced back well and I don’t think I’ve ever seen any other crop do that.”

All-weather crop

Fodder beet also performs well in both wet and dry summers. “We noticed how much deeper rooted the crop was in 2022, due to the drier than typical conditions. It tolerated the more extreme summer and actually outperformed the 2021 crop.

We harvested 98 tonnes per hectare, which we were extremely pleased with,” says Richard, adding that poorer performing crops of different fodder beet varieties have yielded just half that at 50 tonnes per hectares.”

The Whites are planning to grow a similar hectarage of Fosyma in 2023.

“The variety (Fosyma) is the best we’ve ever grown, and we’ll certainly be drilling it again in 2023. Fodder beet has been an essential part of livestock rations and the crop rotation here for 23 years, so that’s not set to change,” adds Richard.

Learn more about Fosyma fodder beet here or contact your usual seed merchant for availability

The latest UK trial results data on fodder beet (including Fosyma) can be downloaded here

Creating carryover maize stocks helps maintain herd performanceA bumper 2023 maize crop looks set to eliminate any future risks of running short of a key forage for one high yielding Dorset dairy herd.

According to Robert Symms, who farms with his wife Bryony and son Jake at Batsons Farm, near Sherborne, growing a slightly increased maize acreage and opting for a top-ranked very early maturing variety should ensure the availability of important carryover silage stocks come the autumn of 2024.

“We’re estimating that we’ve clamped around 2,800 tonnes of maize this year, from 143 acres, so pretty much 20 tonnes/acre,” Robert reports. “That should mean we’ll have enough to last until Christmas 2024, so we can maintain a consistent ration all year round and avoid the issues of previous years when we’ve run short of maize before the new crop is fully fermented.”

Batsons Farm has evolved significantly over the last decade or so, firstly converting to a fully housed operation around 10 years ago, and in the last 12 months moving over to robotic milking. Over this period, a forage ration comprising approximately 60% maize and 40% grass silage has become established, fed as part of a total mixed ration through a forage wagon and underpinning yields that are now pushing up towards 12,500 litres/cow.

The herd currently numbers 220 milking cows, with Robert conscious of the danger of any shortfall in maize production. He therefore turned to his seed supplier, Tim Rutter of Pearce Seeds, for advice on how to boost maize output.

The herd currently numbers 220 milking cows, with Robert conscious of the danger of any shortfall in maize production. He therefore turned to his seed supplier, Tim Rutter of Pearce Seeds, for advice on how to boost maize output.

“Based on the fact that we needed more yield, but still wanted a mature crop harvested before the end of September, Tim recommended Dignity from Limagrain,” Robert adds. “As a new variety, it had performed very well in Pearce Seeds’ own local trials and had all the attributes we were looking for.

“It was £10 a pack more than some of the other alternatives, but it has certainly performed for us, and I can now say it has been well worth the extra investment.”

Maize is usually drilled at Batsons Farm during the first week of May, and 2023 was no exception. It follows an over-winter cover crop of westerwold ryegrass, which provides a bonus cut of forage in early April and helps avoid the risks of bare ground during the wetter months.

“The cover crop will have had slurry on it in March and we apply farmyard manure after we’ve taken the cut of silage,” says Robert. “We then plough in the ryegrass stubble and prepare the ground for drilling with one or two passes with the power harrow. The maize is drilled by our contractor and goes in with one hundredweight to the acre of DAP down the spout. We’ve never seen the benefit of top dressing with any additional nitrogen fertiliser, so it’s simply a case of then allowing our agronomist to advise on herbicides, but our crops are generally pretty clean.”

In what has been a favourable year for growing maize in Dorset, the Dignity has performed exceptionally well,

maturing in good time for harvest before the end of September and yielding an impressive 20 tonnes/acre. Early sampling of the fresh, unfermented crop, taken from the clamp, revealed a dry matter of 34% and an ME of 11.2 MJ/kg, with starch at 28.6%. By the end of November, the fermented crop was analysed at 39.3% DM and 39.0% starch, with an ME of 11.96 MJ/kg. The ensiled crop was also shown to have a high percentage of fast digesting fibre and a low content of non-digestible fibre, both of which will ensure the crop feeds well and is easily assimilated in the rumen.

According to the farm’s nutritionist Vicky Ham, of Kite Consulting, forage budgeting that will, in future, allow the new maize to remain untouched for two or three months will be beneficial to overall herd performance.

“At Batsons Farm, the maize offers vital energy and a safe source of starch and is the foundation for the milkers and dry cow rations. We aim to feed a ratio of 60:40 maize to grass silage but can only do this with adequate silage stocks and fully fermented maize silage.

“When stocks run short, as we’ve seen this year and in previous years, there’s a risk of upsetting the rumen balance, and feeding the maize before the starch is at its most digestible equates to lost production potential.

“With the increased stocks resulting from the improved 2023 harvest with LG Dignity, we’re in a much better position from a forage budgeting perspective. Next year the new-season maize should remain untouched for two to three months after clamping and that will mean we’re maximising its value in the ration.”

With regards to the grass silage component of the ration, the Symms have moved towards a multi-cut system in recent years, starting early and taking as many as five or even six cuts a season, to maximise silage quality.

With input again from Pearce Seeds, they are now looking at four-to-five-year leys, with the addition of very large leaf white clover, which will not only boost the protein value of the grass silage but could also help to secure additional payments through the new Sustainable Farming Incentive schemes.

King of the cropLG Monarch grass seed mixtures come up trumps on North Yorkshire sheep farm

Livestock farmer Andrew Hollings relies on good quality grass for his 1,000 hill ewes and small beef herd situated in Goathland, in the North Yorkshire National Park.

The farm is a mixture of moors and lower lying grass leys. Andrew, who is the third generation of the family to farm at Liberty Hall, has a system designed to suit the area. His Swaledales and Cheviots are hardy enough for the moors. These are crossed with a Leicester tup, and the lambs are reared and finished on the lower land. Lambing starts in early April.

“It’s soon enough up here,” says Andrew, who has noticed a change in conditions during his farming career. “We’ve always worked with the weather not against it,” he adds.

“We’re just 10 miles in land from Whitby and we seem to get stronger winds coming off the North Sea,” he says. “These winds are our biggest challenge. It can be very wet, then the winds pick up and they dry out the ground. Summers are drier and warmer than they were 30 years ago. These conditions are harsh on the grass crops. We have to adapt our system to maintain and improve productivity.”

Mindful that grass must remain ‘king’ on both Liberty Farm’s 93-hectares and the blocks of rented land, Andrew has become more discerning on grass seed mixture choices and he’s started using options that are more suited to conditions and to coping with the challenges, all while improving feed value and productivity.

“I want as much feed value from homegrown forages,” he adds. “I rely mainly on grazed grass and some haylage. In very dry summers, we’ve seen the ground dry up and grass becomes short. In 2022, when it was particularly dry, the feed value in the grass dropped and ewe productivity fell and there were more single lambs.”

The knock-on effect of this changing weather pattern has made Andrew look more carefully at improving grass productivity to safeguard home grown forage supplies. And it’s seen a move to better quality grass seed and multispecies mixtures.

He’s taken some advice from BATA’s agronomist Rose Thompson, and in 2021, he moved to using LG Monarch mixtures; partly because their range has mixtures designed for specific environments and purposes and also because the mixtures, designed by seed breeding company Limagrain, have been tried-and-tested in UK conditions.

“I look to reseed 15 to 20 acres (six to eight hectares) a year,” adds Andrew. “Grass is the cheapest feed we have. If I can improve the quality, it pays dividends.”

He opted for LG Monarch FlexiScot, which is a long-term mixture with highly productive tetraploid and diploid rye grasses, for early growth, and Timothy and white clover varieties that mature in mid-summer and offer some drought resistance.

This mixture has excellent winter hardiness, and it has been tested successfully, across Scotland and Northern England.

Andrew directly drilled the Flexiscot seed after a crop of stubble turnips which were grown as a break crop. “We put plenty of muck on the land and a bit of fertiliser when we shut it up – this is hungry land.”

In fact, Andrew soil tests the land every year. “It’s vital that we get the pH right – it’s acidic soil and we need to lime it regularly, applying about 3t/acre (1.5t/ha).”

The resulting crop was highly successful and produced a dense sward that came out very well when analysed as part of the farm’s Flock Health Plan. “It’s a mixture that I will continue with – the yield and quality in year one and two has been phenomenal.”

Sheep at Liberty Hall graze the lower-lying grass swards until mid-May when they are closed up for six weeks before cutting for haylage for feeding ewes in January to March when there’s no feed value in neither the grass nor heather.

“I’m really pleased with the amount of grass we get off it,” he adds. “The swards are yielding very well with good quality grass and they’re lasting well through summer. This mixture is a big improvement on the previous ones.”

Another mixture Andrew introduced just recently is LG Monarch Multi-species. This medium-term herbal ley grazing mixture includes later perennial ryegrass, Timothy, red and white clover, chicory, sainfoin, fescues and plantain. The legume varieties reduce fertiliser input requirements and drought resistant species see the crop thriving during summer.

“I sowed 13-acres (5-ha) in mid-September 2022 – just power-harrowed the field and disced in the seed. It grew well. It didn’t need fertiliser, there were no growth checks. It was ready for grazing in spring and the sward remained very green throughout the summer.

“I sowed 13-acres (5-ha) in mid-September 2022 – just power-harrowed the field and disced in the seed. It grew well. It didn’t need fertiliser, there were no growth checks. It was ready for grazing in spring and the sward remained very green throughout the summer.

“In fact, it grew so vigorously early in the season, that we had to cut and bale some. The aftermath went on to make excellent grazing right through summer for the lambs. We’ve grown more multicut now – it’s an ideal mixture for our lower-lying fields.

“These improved mixtures prove that it’s not what the grass seed costs, but it’s what it does that’s important.”

IDEAL FEED FOR SHEEP

Limagrain forage crop account manager, Henry Louth, says that Mr Hollings’s experience with specific LG Monarch grass seed mixtures demonstrate the mixture’s potential to work well in harsher conditions.

“This makes them ideal for upland sheep farmers,” he says.

“Limagrain promotes its LG Monarch range, particularly the Flexiscot, Multicut and Multigraze mixtures to sheep farmers. Not only do they grow well, even in less than perfect conditions, they provide high feed value. Sheep and cattle also do particularly well on these forages.”

He is also seeing more interest in the Monarch Multi-species mixture. “This is ideal for low-input grazing, and it provides a grazing crop throughout summer and in drier conditions. As the grass growth slows down, other varieties in the mixture, like chicory, keep growing.”

Find out more about our grass mixtures here

County Durham estate finds perfect variety fit for regen systemA large estate in the North east of England, has turned to wheat variety LG Typhoon as part of its drive to build a more sustainable regenerative cropping system.

The in-house farming operation of County Durham-based Raby Estates began conversion to direct drilling in 2018 and is striving to reduce the use of artificial inputs where possible, without compromising on the quality and quantity of crops produced.

Philip Vickers

It is a challenge that the variety lived up to last season, according to farm manager Philip Vickers, who decided to trial the variety on the recommendation of Limagrain UK’s arable technical manager, Ron Granger.

“We’re trying to move away from growing high input varieties, so are primarily looking for those that offer a robust disease package, good standing power and suitability for our direct drilling system,” Mr Vickers says.

“Direct drilling in northern England is not something you want to be doing into November, so I also look for varieties that suit the early drilling slot. From what we’ve seen so far, LG Typhoon seems to fit our requirements well.”

Strong performance

Last season the farm grew around 32 ha (80 acres) of LG Typhoon, alongside several other varieties, but Mr Vickers has been so impressed with its agronomics, ease of management and yield performance, that he plans to increase this to 100 ha for 2023/24.

The LG Typhoon averaged an excellent 9.4-9.6 t/ha. A number of weather-related challenges throughout the season however, including exceptionally high Septoria pressure, did not make for an easy growing season.

The LG Typhoon was direct drilled in mid-September as a first wheat after oilseed rape, using the farm’s 6-metre Horsch Avatar, or 6-metre Väderstad Seed Hawk, drills. Seed rates were kept relatively high at around 300/m2, to counter the slightly lower establishment percentage experienced when direct drilling.

All crops received a base application of phosphate and potash fertiliser, plus a total of up to 170 kg N/ha in the spring, applied as three splits; the first as granular urea, followed by two liquid nitrogen applications.

“We have been reducing nitrogen use significantly in recent years, but in contrast to conventional thinking, some crop yields have gone up in that period,” Mr Vickers notes.

“Agronomy-wise, LG Typhoon was problem-free,” he continues. “It established quickly in the autumn, got away well in the spring, and was relatively early to harvest, tight behind Graham.”

But even though it established quickly, he says LG Typhoon did not get too large, unlike some other varieties, which continued tillering throughout a very mild autumn, during which temperatures hit 21°C in November. Those varieties then became much harder to manage with growth regulators and fungicides in the spring.

Robust disease profile

Strong Septoria resistance is a must-have for all winter wheat varieties grown on the farm, as the disease remains the number one yield-robber in high pressure seasons such as 2023, Mr Vickers says. “We generally look for varieties with a Recommended List score of at least six.”

With a Septoria rating of 7.3, backed up by a combination of genetics that are different to those in other RL varieties, giving LG Typhoon a distinct advantage over other varieties.

Although crops received the farm standard fungicide programme, based around Iodus (laminarin) at T0, bixafen/prothioconazole at T1, Univoq (fenpicoxamid + prothioconazole) at T2, and straight tebuconazole at T3, he was able to reduce rates by 10-15% on the LG Typhoon due to its robust disease profile.

“To ease management, we generally try to keep fungicide products similar across all varieties, but will look to vary the rate where appropriate.

“Despite doing so on the LG Typhoon, we still didn’t see any disease of significance at all last season, even though there was very high Septoria pressure which caused some other varieties to struggle.”

Accurate spray timing is also key to maintaining effective disease control, as is a robust trace element programme to bolster plant health and reduce the crop’s susceptibility to disease infection, he adds.

Perfect fit for regen systems

Mr Granger says LG Typhoon has certain attributes that make it ideally suited to strip tillage/direct drilling, regenerative crop establishment systems, that often feature wider rows.

LG Typhoon’s growth habit, for example, means plants sit prostrate with slower growth through the winter into spring, which is ideal for those direct drilling earlier in the autumn and who do not want a variety that races off too quickly.

It is a high tillering variety that has the capacity to utilise the space between the wider rows, often found with some direct drilling equipment.

Indeed, while Mr Vickers’s Horsch drill works on a standard row spacing, the Väderstad is at a slightly wider 180-200 mm spacing, and he also trialed a new 12-metre tine drill last season, which worked on a wider 250 mm row width.

“Unfortunately, we don’t yet have the yield data available, as the demo field was combined by a contractor, but the LG Typhoon did seem to really suit that wider row spacing. It’s something we may potentially look at in the future, although I’m not sure a 12-metre machine is suited to some of the smaller fields on our farm.”

Another attribute of LG Typhoon that makes it a good fit for regenerative systems, and for those looking for flexibility with crop protection inputs, is its strong standing power and disease resistance – reflected by its high untreated yield (92%), Mr Granger says.

Unlike some other feed varieties, it also offers Orange Wheat Blossom Midge (OWBM) resistance, in addition to a six-rating for eyespot and Fusarium.

“It’s a high yielding, consistent and resilient variety, that delivers across seasons and rotations.”

Raby Farms

- In-house farming division of Raby Estates (Shropshire and County Durham)

- The Durham farm typically grows 500-600 ha of winter wheat, mainly hard Group 4 feed

- Cropping also includes winter barley, oilseed rape and beans

- Started conversion to direct drilling in 2018

- Looking to develop a more regenerative system, reducing reliance on artificial inputs

- Started growing LG Typhoon in 2022/23

- High yielding hard Group 4 feed wheat

- Consistent performance across different seasons and regions

- Excellent disease resistance, especially Septoria (7.3) and yellow rust (9) – high untreated yield (92%)

- OWBM resistance

- Growth habit suits early drilling and wider row regenerative systems

- Excellent performance as a second wheat

Two row winter barley, LG Caravelle, joined the AHDB RL last year as a contender to match hybrid barley yields, and early harvest reports confirm that it has lived up to its promise.

Despite the challenging season, the variety has performed well on the Yorkshire Wolds. Mark Ullyott of Langtoft Grange Farm near Driffield, is really pleased with his seed crops of LG Caravelle, yielding between 8.5-9.5 t/ha.

“We have grown seed crops of barley for over 10 years, and LG Caravelle must be the best we have seen,” he says.

He grew two fields this year: one following vining peas and the other after potatoes. The crop following the vining peas was drilled on the 28th September at the standard seed rate of 300 seeds/m2. This field was ploughed, pressed & combination drilled.

The field following the potatoes was min-tilled and went in a bit later, on the 23rd October, with a slightly higher seed rate of 350 seeds/m2, to compensate for the later drilling.

Both fields established well and looked pretty good. “We don’t have too much of a black-grass issue, so a pre-emergence application of flufenacet and diflufenican at 0.4 l/ha and some Avadex, pretty much tidied up any weeds,” explains Mark.

Disease-wise, the crop stayed clean with a standard fungicide programme, and received 160 kg of Liquid N32/ ha, which was reduced slightly due to the increased fertiliser costs at the time.

“It’s a fairly tall variety, so we used a ‘bottom-shortening’ PGR, chlormequat, but I think the crop would benefit from a ‘top shortener’ as well next time, just to reduce its height that bit more, although it’s important to note the straw strength was good and we didn’t have any lodging or brackling issues.”

“Both fields were ready to harvest by the third week of July, but the wet weather meant the field following the vining peas was ready first on the 31/7 but we had to hold on for another week for the second field, again due to the weather.”

“Despite this, the crop held its own, germ still looked good and bushel weight held up with no sprouting. The straw came off well; all of which goes for home use,” he adds.

“It is always interesting growing a new variety for the first time to see how it performs, and we are very pleased with LG Caravelle and will grow it again. If we could, we would put all of our acreage down to the variety,” says Mark.

LG Caravelle joined the 2023/24 Recommended List as the highest yielding two row winter barley.

“We launched the variety not just on the back of its high yields but with a confidence that the variety would deliver across a range of conditions,” says Ron Granger, Limagrain’s arable technical manager.

“The years running up to its recommendation were dry and the variety yielded exceptionally well, however this season has been much wetter but LG Caravelle has upheld its promise of consistency and delivered the yields – and that’s a very valuable attribute on farm.”

Ron explains LG Caravelle’s yield potential is backed up by its specific weight. “Specific weight is important no matter what, and LG Caravelle’s is very high at 71.8 kg/hl. It’s one of the best scores available and is only surpassed by KWS Cassia.”

LG Caravelle’s yield potential is also bolstered by its disease resistance profile, says Ron. “The variety has a 7 for mildew, a 6 for rhynchosporium and a 5 for net blotch,” he explains. “Although there’s no rating on the RL yet, our data indicates the variety scores a 7 against brown rust, which is high against this disease.”

The variety also has resistance to barley yellow mosaic virus, giving it all round disease resistance, he adds. “The culmination of this can be seen in its untreated yield.” “It has a very high untreated yield of 89%, which really gives growers security,” he adds.

Ron feels that growers who’ve been growing hybrids might be interested in returning to two-rows because of LG Caravelle’s performance. “Hybrids account for about 20-25% of the winter barley market but this could change. Plus, we’re currently testing to see if LG Caravelle could be suitable for more than just the feed market.”

“We’re seeing the next step in on-farm varietal security for farmers and these types are proving to be an option on-farm again.”

Fungicide programme:

Esfenvalerate 2.50%, was applied at growth stage 14.

6th May: T1 consisting of Cyprodinil 30.00%, Tribenuron-methyl 14.30%, Metsulfuron-methyl 14.30%, Florasulam 0.25%, Fluroxypyr 10.00%, Trinexapac-ethyl 25.00%, and Folpet.

6th June: T2 consisting of prothioconazole 25.00%, trifloxystrobin 8.80%, and prothioconazole 17.50%.