The challenges of dry summers and increasing input prices have tempted one East Lothian beef farmer into trying out fodder beet for finishing his beef cattle.

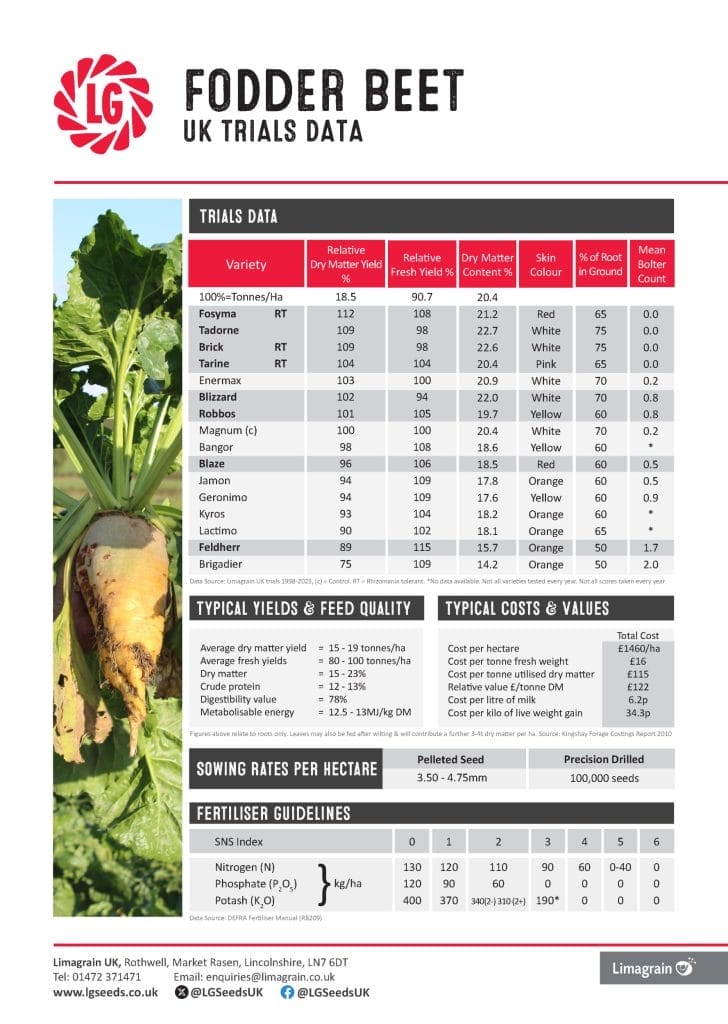

And Anderson Waddell has no regrets, and for now, he’s committed to a crop each year. In May 2023, his contractors sowed six hectares of plant breeder Limagrain’s Robbos fodder beet and lifted about 120 tonnes per hectare fresh weight (50t/acre) of the crop in November. He’s recorded good intakes of this high energy feed and found an improvement in the finished cattle.

Anderson runs the 150-hectare beef and arable family farm at Pencaitland, East Lothian, 14 miles southeast of Edinburgh. He buys about 90 six-month old male calves, mainly from one farmer, between October and December each year. Most are pure Charolais, and the rest – about 25% – are Limousin.

Anderson runs the 150-hectare beef and arable family farm at Pencaitland, East Lothian, 14 miles southeast of Edinburgh. He buys about 90 six-month old male calves, mainly from one farmer, between October and December each year. Most are pure Charolais, and the rest – about 25% – are Limousin.

These calves go out to grass the following spring at around 300kg liveweight and are then housed from 430kg to finishing weights of 650kg to 700kg.

Indoors, cattle get a diet of grass silage and homegrown barley in troughs which this year has been mixed with chopped fodder beet.

“By October each year I can have about 280 cattle on the farm, so I need a reliable source of high quality feed,” he says, adding that the dry summers have knocked back silage yields and increasing input prices have affected the cost of growing barley.

“So I was keen to look at alternative home grown feeds to eke out supplies of silage and reduce my reliance on feed barley. I am to be self-sufficient in feed supplies.”

Many friends in the area grow fodder beet so Anderson asked around for some tips and took the recommendation from his seed merchant Dods of Haddington.

“The reliability and consistency of fodder beet yields, and its feed value made it an attractive option, and the variety Robbos, which is tried and tested was recommended and a lot around here grow it,” he adds. “So it seemed like a good option to start with.”

The crop was sown into prepared land following barley. Anderson applied plenty of dung on the stubble prior to ploughing and preparing the seed bad.

“Input costs after sowing were relatively small – just three weed treatments were applied between May and June. Establishment was good and despite some dry conditions, the crop kept growing.”

His contractor lifted the crop in November – which Anderson admits was a bit late in view of the wet conditions. “But it yielded well and it’s certainly taken pressure off the silage and barley. Cattle have grown well and they’re killing out better.”

He wants to improve the chopping equipment – last winter he used a Ritchie Root bucket feeder, which was not ideal. “I’ve still a bit to learn with growing and feeding fodder beet but it’s just what I needed in the diet and it’s cost-effective,” he adds.

“And I also have plenty of organic matter on the field to promote soil health ahead of the next crop of spring barley that will be drilled in May. So, fodder beet is giving me just what I wanted from a forage crop – it’s a win-win for now.”

Find out more about Robbos fodder beet here and download our latest UK trial results for fodder beet.

Highest yielding Recommended varieties on show at CerealsPlant breeders Limagrain UK will showcase their impressive portfolio of varieties across crop sectors at Cereals 2024.

After several years absence from Cereals, the breeders have returned to the Event on the back of their resounding success on the 2024/2025 AHDB Recommended List.

“Producing the highest yielding varieties, backed up with desirable agronomic characteristics is an exceptional achievement for any breeder. What’s more, these varieties have proven to be robust and consistent performers across seasons and regions,” explains Ron Granger, Limagrain’s arable technical manager.

Visit stand 606 to find out more about the highest yielding winter wheat LG Beowulf, LG Caravelle the highest yielding 2-row winter barley and the highest gross output oilseed rape varieties LG Armada, LG Adeline and LG Academic.

Visit stand 606 to find out more about the highest yielding winter wheat LG Beowulf, LG Caravelle the highest yielding 2-row winter barley and the highest gross output oilseed rape varieties LG Armada, LG Adeline and LG Academic.

There will also be experts on hand to discuss Limagrain’s very diverse portfolio, including maize, forage crops and SFI options as well as an opportunity to enter a prize draw to win free seed.

“We are here to listen and share our expertise on how to get the very best out of Limagrain genetics, and the Cereals Event gives us the opportunity to do this directly with the farming community we serve,” he says.

Visit LG on stand 606, buy tickets here

Modern fodder beet suits arable rotation and provides essential livestock feedBrothers Richard and Fred White who run a 650-hectare mixed farm have grown fodder beet as part of their crop rotation for the past 23 years

Brothers Richard and Fred White run a 650-hectare mixed farm, comprising beef, sheep and arable enterprises, in Warwickshire, and they’ve grown fodder beet as part of their crop rotation for the past 23 years, waxing lyrical about its record yields and its part in ticking a lot of boxes in their farming system.

They began growing Limagrain UK variety Fosyma in 2020 after a recommendation from Wynnstay’s Emma Edwards. This high-dry-matter fodder beet variety is pink-skinned and conical-shaped, and it combines a dry matter content of between 20% and 21% with a relatively high proportion of its root (40%) out of the ground, leaving just 60% in the ground.

Essential part of the rotation

“It fits well into our rotation, usually following and preceding winter wheat,” explains Richard. “We also grow forage maize to feed to the 180-head beef herd, as well as oats and barley, which is also rolled and fed to livestock.”

He and Fred thought Fosyma would do well on their Tamworth-based farm, particularly because they lift and feed fodder beet to their Hereford cattle and sheep during the winter.

It’s medium-depth root reduces the risk of soil contamination and offers flexible feeding and end-use options. Their contractor uses root-lifting equipment, typically harvesting the 23 hectares of the crop that they grow each year. Soil contamination has never been an issue for the Whites.

Market options

They store and feed approximately 50% of the fodder beet to their own sheep and cattle. The other half is sold off farm, for between £45 and £50 per tonne. Some has gone to AD plants, and some has also been sold to feed to deer om a nearby estate.

“They really enjoy fodder beet – as do our cattle and sheep. They all do really well on it.”

Producing home-grown feed and forage is a priority for the brothers, but fodder beet is also a useful break crop. “We typically sow is at the end of April, after applying plenty of manure,” explains Richard, adding that the farm comprises a mixture of different soils.

Producing home-grown feed and forage is a priority for the brothers, but fodder beet is also a useful break crop. “We typically sow is at the end of April, after applying plenty of manure,” explains Richard, adding that the farm comprises a mixture of different soils.

“We have heavy, medium and light soils and the crop is sown across them all – we mix it up. And is performs well – we always see good yields.”

Once in the ground, Richard says the fodder beet ‘doesn’t hang about’. “It germinates and grows quickly. We do need to control weeds, to prevent competition, but once well established the crop’s canopy helps to suppress them.”

The crop is typically ready for harvest at the end of September, but they leave it in the ground until lifting in mid-October. As soon as the beet is lifted, they’re ready with the drill and sow winter wheat into the ground. So they’re not leaving the land fallow over winter.

Palatable yields

For the past three years Fosyma has yielded between 30 tonnes and 35 tonnes per acre (75 tonnes and 87 tonnes per hectare). It’s stored outside in a clamp made from straw bales and feeding to outwintered livestock starts when grass growth slows, which is usually at the end of October.

“It’s fed whole, on the ground, to cattle and sheep. We don’t have to chop it. And they love it – there’s no waste.”

Richard adds that as well as adding ‘interest’ to winter rations, fodder beet also supports lamb growth.

The 450-ewe flock lambs in late April, and lambs are finished on the farm’s 400 acres (160-hectares) of permanent pasture and fodder beet during the winter. “We start selling lambs in January, at around 45kg LW,” he says.

The 450-ewe flock lambs in late April, and lambs are finished on the farm’s 400 acres (160-hectares) of permanent pasture and fodder beet during the winter. “We start selling lambs in January, at around 45kg LW,” he says.

Home grown forage saves £

“We don’t buy in any feed or concentrates for the ewes or the lambs – the system is completely forage based.”

The beef enterprise is also predominantly grass based, with only home-grown cereals fed as part of winter ration when cattle are housed. Cattle are finished and sold, at between 24 and 30 months, to local butchers in Atherstone

In 2021, Richard grew a crop that looked very ‘bare’. “The seed went in well, as usual, but were no beet plants and there were no weeds either. It was odd and Limagrain UK’s Brian Copestake came to take a look because I was at a loss as to what had happened.

“He said it was a flea beetle problem and while I was deliberating about re-drilling, the field suddenly sprouted green rows of beet plants. It soon caught up and within weeks we had a field full of strong and healthy beet that as well up to calf level. It bounced back well and I don’t think I’ve ever seen any other crop do that.”

All-weather crop

Fodder beet also performs well in both wet and dry summers. “We noticed how much deeper rooted the crop was in 2022, due to the drier than typical conditions. It tolerated the more extreme summer and actually outperformed the 2021 crop.

We harvested 98 tonnes per hectare, which we were extremely pleased with,” says Richard, adding that poorer performing crops of different fodder beet varieties have yielded just half that at 50 tonnes per hectares.”

The Whites are planning to grow a similar hectarage of Fosyma in 2023.

“The variety (Fosyma) is the best we’ve ever grown, and we’ll certainly be drilling it again in 2023. Fodder beet has been an essential part of livestock rations and the crop rotation here for 23 years, so that’s not set to change,” adds Richard.

Learn more about Fosyma fodder beet here or contact your usual seed merchant for availability

The latest UK trial results data on fodder beet (including Fosyma) can be downloaded here

Forage outlook and options for 2024The climate is keeping us on our toes and this year (2023) has been no exception. It calls for flexibility and agility when it comes to growing forage crops. Limagrain’s forage crop manager John Spence sows some seeds of ideas on future proofing home grown feed supplies going forward.

“We’re ending the year with decent stores of grass and maize silage, but this doesn’t tell the full story,” says John Spence. “A cold late spring delayed grass growth, then for most grass silage making started well, until heavy rain arrived.

Hot and dry conditions weren’t as extreme as 2022, but some were affected with poor grass growth, then some respite and good grass growth through a mild autumn until heavy rain put some areas under water at worst and at best caused the late sowing of forage catch crops which will certainly hamper their yield and quality.

Hot and dry conditions weren’t as extreme as 2022, but some were affected with poor grass growth, then some respite and good grass growth through a mild autumn until heavy rain put some areas under water at worst and at best caused the late sowing of forage catch crops which will certainly hamper their yield and quality.

So farmers are faced with balancing more extreme weather conditions and the drive to improve sustainability and economic viability by producing more feed value from home grown forages.

“Marrying the two is quite a challenge,” adds Mr Spence.

“Agility and flexibility are key when it comes to planning. Avoid planning everything in stone and being too rigid with the cropping.”

Forage choices

The dairy system will determine forage options, with more alternatives typically possible in grazing herd situations. “A herd housed full time will usually rely on conserved high quality silages. “This has to remain the priority,” says Mr Spence. “But introducing forages like fodder beet and forage rye can really boost output from homegrown forages, as well as opting for higher production grass seed mixtures and clovers.

“Grazed herds can consider kale too, and some brassicas like Skyfall that ‘bounces back’, in effect giving two grazing crops, through summer which can take the pressure off the grass.”

Fodder beet, though, has been used in dairy cow diets for many years in areas where it can be grown on farm or locally on contract.

“This is a high energy crop, highly digestible and ‘enjoyed’ by dairy cows. We’ve tested a range of varieties in our own UK farm trials for more than 10 years and yields are consistently reliable, even in dry hot summers,” he adds.

“And new modern varieties are out-performing some of the older fodder beets. Limagrain trials consistently show the variety Fosyma to have the best dry matter yield at 14% above the control variety Magnum, and 5% above its closest rival Brick.”

Fodder beet’s feed value at 78% digestibility and 13MJ/kg of dry matter is a valuable addition to any dairy ration.

Kale might have been out of fashion. “But not anymore,” adds Mr Spence. “Here again, new varieties with improved feed value have brought the crop back into the spotlight.”

He highlights Bombardier – a relatively new kale variety with a nutritious stem and leaf with 72% digestibility in UK trials and 17% crude protein It’s sown between April and June so it can follow first cut silage and provide a valuable break crop in the grass rotation.

“A kale crop can slot into the plan for many grazing herds. It’s fast-growing so cattle can strip graze it as a buffer feed in mid-summer to take the pressure off the grass.

But it has a long shelf-life too, so it’s a useful crop for youngstock and dry cows in autumn and winter. In either situation it can be used as a break crop and followed with a grass reseed. Break crops between grass crops are increasingly important in breaking the pest cycle and improving productivity of grass leys.”

Forage rye has been particularly popular this autumn – 2023, with crops following harvest or early maturing maize varieties. It can be sown until late October and is ready for cutting or grazing in early spring, even before Italian ryegrass.

A crude protein content of 12% and an ME of 10MJ/kg DM makes it an ideal forage for late lactation or dry cows, or youngstock. And once finished, the field can go back into maize or a spring reseed.

“A crop of rye will provide a valuable feed to eke out silages and it’s also a great crop to mop up residual nutrients and maintain soil health. The only caveat maybe sowing in a very wet autumn, but most farmers were in time this year, as the first half of autumn was warm and dry. So again, a flexible approach is needed and the will to act if conditions are right.”

Grass is king

Grass is the most important forage for most dairy farmers, and increasing its productivity and feed value should be on-going. This includes regular reseeding and taking advantage of improved grass seed mixtures and always selecting a grass seed mixture to suit the system and purpose of the crop, as well as the growing conditions and soil type.

“There are new varieties, improved grass seed mixtures and enhancements to match changing conditions. So farmers should seek advice and look for mixtures with proven trial results and good performance on UK farms and be discerning in their choices,” adds Mr Spence.

Limagrain trials in 2020 highlight the benefit of reseeding and of selecting proven mixtures. Table 1 highlights the productivity of a one year old ley and a four year old ley. The additional 45% of energy produced by the new sward was equivalent to more than 6,000 litres of milk (assuming 5.3MJ/litre).

Table 1

|

|

Age of Sward (Years) |

|

|

|

|

4 |

1 |

Benefit of New Ley |

|

1st Cut DM yield (t/ha) |

3.57 |

6.06 |

+2.49 |

|

ME (MJ/kg DM) |

10.8 |

11.9 |

+1.1 |

|

ME yield (MJ/ha) |

38,669 |

72,072 |

33,403 |

Source: Limagrain UK Trials, May 2020

“The additional energy yield value from younger leys will increase the proportion of milk yield from home-grown forage, reduce bought-in feed costs and this will justify the cost of the reseed. Depending on the age and quality of the ley, estimates suggest the additional yield in year one of a reseed will cover its cost.”

Trials have also demonstrated the benefits of improved mixtures with proven feed values. LGAN is the accreditation given to LG mixtures that meet the company’s combined yield and feed value criteria, and table 2 shows the performance range at first cut of the one-year-old mixtures on trial.

Trials have also demonstrated the benefits of improved mixtures with proven feed values. LGAN is the accreditation given to LG mixtures that meet the company’s combined yield and feed value criteria, and table 2 shows the performance range at first cut of the one-year-old mixtures on trial.

“The best performing mixture at first cut was LGAN Quality Silage, which produced more than 7t/DM of 12.5ME silage. The trial year, 2020, was particualrly dry, so these results demonstrate the big gains that can be made by using high-feed-value mixtures.”

Table 2

|

|

Max |

Min |

Range |

|

DM yield (t/ha) |

7.81 |

4.78 |

3.03 |

|

ME (MJ/kg) |

12.5 |

11.6 |

0.9 |

|

ME yield (MJ/ha) |

93,703 |

55,384 |

38,319 |

Stock up on clover

A forage outlook for 2024 wouldn’t be complete without highlighting the benefits of clover in grass leys.

“Any new reseed with clover in the mix or overseeding a ley with clover is eligible for an annual payment of £102 a hectare under the new SFI action NUM2 (Legumes on improved grassland),” says Mr Spence.

“This more than pays for the seed, and it brings all the benefits in soil health, nitrogen fixing and feed value. And in mid-summer, the clover provides good feed value when perennial ryegrass growth slows down.”

A lot of focus is also being placed on multispecies leys, with sustainability schemes encouraging dairy farmers to integrate them into their systems. “There are payments available under the new SFI scheme for sowing multispecies leys which will be worth investigating in the forage planning for 2024.

A lot of focus is also being placed on multispecies leys, with sustainability schemes encouraging dairy farmers to integrate them into their systems. “There are payments available under the new SFI scheme for sowing multispecies leys which will be worth investigating in the forage planning for 2024.

“There is a lot of considerations and it’s worth having an open mind to new ideas and options.”

FORAGE PLANNING POINTERS

- Plan to increase output from homegrown forages

- Throw the net out wider – look at all the options

- Have a flexible plan and be agile to adapt to the season’s weather conditions

- Have a robust and productive rotation for the farm – no one rotation fits all

- Use a forage break crop between grass reseeds

- Look at improved forage crop varieties with better protein and energy contents

- Clover in grass leys is a must

- Improving grass quality and feed value is on-going

- Carefully select grass seed mixtures with proven feed value

For more info on forage options to suit your farm business, click here or download the LG Essential Guide to Forage Crops

King of the cropLG Monarch grass seed mixtures come up trumps on North Yorkshire sheep farm

Livestock farmer Andrew Hollings relies on good quality grass for his 1,000 hill ewes and small beef herd situated in Goathland, in the North Yorkshire National Park.

The farm is a mixture of moors and lower lying grass leys. Andrew, who is the third generation of the family to farm at Liberty Hall, has a system designed to suit the area. His Swaledales and Cheviots are hardy enough for the moors. These are crossed with a Leicester tup, and the lambs are reared and finished on the lower land. Lambing starts in early April.

“It’s soon enough up here,” says Andrew, who has noticed a change in conditions during his farming career. “We’ve always worked with the weather not against it,” he adds.

“We’re just 10 miles in land from Whitby and we seem to get stronger winds coming off the North Sea,” he says. “These winds are our biggest challenge. It can be very wet, then the winds pick up and they dry out the ground. Summers are drier and warmer than they were 30 years ago. These conditions are harsh on the grass crops. We have to adapt our system to maintain and improve productivity.”

Mindful that grass must remain ‘king’ on both Liberty Farm’s 93-hectares and the blocks of rented land, Andrew has become more discerning on grass seed mixture choices and he’s started using options that are more suited to conditions and to coping with the challenges, all while improving feed value and productivity.

“I want as much feed value from homegrown forages,” he adds. “I rely mainly on grazed grass and some haylage. In very dry summers, we’ve seen the ground dry up and grass becomes short. In 2022, when it was particularly dry, the feed value in the grass dropped and ewe productivity fell and there were more single lambs.”

The knock-on effect of this changing weather pattern has made Andrew look more carefully at improving grass productivity to safeguard home grown forage supplies. And it’s seen a move to better quality grass seed and multispecies mixtures.

He’s taken some advice from BATA’s agronomist Rose Thompson, and in 2021, he moved to using LG Monarch mixtures; partly because their range has mixtures designed for specific environments and purposes and also because the mixtures, designed by seed breeding company Limagrain, have been tried-and-tested in UK conditions.

“I look to reseed 15 to 20 acres (six to eight hectares) a year,” adds Andrew. “Grass is the cheapest feed we have. If I can improve the quality, it pays dividends.”

He opted for LG Monarch FlexiScot, which is a long-term mixture with highly productive tetraploid and diploid rye grasses, for early growth, and Timothy and white clover varieties that mature in mid-summer and offer some drought resistance.

This mixture has excellent winter hardiness, and it has been tested successfully, across Scotland and Northern England.

Andrew directly drilled the Flexiscot seed after a crop of stubble turnips which were grown as a break crop. “We put plenty of muck on the land and a bit of fertiliser when we shut it up – this is hungry land.”

In fact, Andrew soil tests the land every year. “It’s vital that we get the pH right – it’s acidic soil and we need to lime it regularly, applying about 3t/acre (1.5t/ha).”

The resulting crop was highly successful and produced a dense sward that came out very well when analysed as part of the farm’s Flock Health Plan. “It’s a mixture that I will continue with – the yield and quality in year one and two has been phenomenal.”

Sheep at Liberty Hall graze the lower-lying grass swards until mid-May when they are closed up for six weeks before cutting for haylage for feeding ewes in January to March when there’s no feed value in neither the grass nor heather.

“I’m really pleased with the amount of grass we get off it,” he adds. “The swards are yielding very well with good quality grass and they’re lasting well through summer. This mixture is a big improvement on the previous ones.”

Another mixture Andrew introduced just recently is LG Monarch Multi-species. This medium-term herbal ley grazing mixture includes later perennial ryegrass, Timothy, red and white clover, chicory, sainfoin, fescues and plantain. The legume varieties reduce fertiliser input requirements and drought resistant species see the crop thriving during summer.

“I sowed 13-acres (5-ha) in mid-September 2022 – just power-harrowed the field and disced in the seed. It grew well. It didn’t need fertiliser, there were no growth checks. It was ready for grazing in spring and the sward remained very green throughout the summer.

“I sowed 13-acres (5-ha) in mid-September 2022 – just power-harrowed the field and disced in the seed. It grew well. It didn’t need fertiliser, there were no growth checks. It was ready for grazing in spring and the sward remained very green throughout the summer.

“In fact, it grew so vigorously early in the season, that we had to cut and bale some. The aftermath went on to make excellent grazing right through summer for the lambs. We’ve grown more multicut now – it’s an ideal mixture for our lower-lying fields.

“These improved mixtures prove that it’s not what the grass seed costs, but it’s what it does that’s important.”

IDEAL FEED FOR SHEEP

Limagrain forage crop account manager, Henry Louth, says that Mr Hollings’s experience with specific LG Monarch grass seed mixtures demonstrate the mixture’s potential to work well in harsher conditions.

“This makes them ideal for upland sheep farmers,” he says.

“Limagrain promotes its LG Monarch range, particularly the Flexiscot, Multicut and Multigraze mixtures to sheep farmers. Not only do they grow well, even in less than perfect conditions, they provide high feed value. Sheep and cattle also do particularly well on these forages.”

He is also seeing more interest in the Monarch Multi-species mixture. “This is ideal for low-input grazing, and it provides a grazing crop throughout summer and in drier conditions. As the grass growth slows down, other varieties in the mixture, like chicory, keep growing.”

Find out more about our grass mixtures here

Limagrain provides feed for endangered bird speciesThe campaign to increase numbers of turtle doves in the UK and stave off extinction of this endangered species is benefitting from feed supplies from seed company Limagrain UK.

Donations of small seeds typically turnips and peas and oilseed rape screenings from the company’s seed plant in Norfolk, that would otherwise be wasted, are supporting birds on the independent Turtle Dove Breeding Project. This project, co-ordinated by Trevor Lay of Waveney Wildlife, supplies all the captive bred birds to the Turtle Dove Trust for release purposes.

“We use mostly domestic, fostering Java Doves and we also encourage the Turtle Doves to rear at least one or two broods themselves,” says Trevor.

The breeding project supplies around 500 turtle doves each year, free of charge. The majority to the Turtle Dove Trust, and to other conservationists or release projects.

Trevor puts the seed material on a range of different ground surfaces such as scrubby grass, gravel, different sand types, ballast and granite chippings, so the young birds get used to foraging for all their seeds. “They are then familiar with searching on different terrain when they are released.

“We aim to release over-wintered birds once the oilseed rape and barley harvest is well underway, so the birds have plentiful feed supplies locally and are not tempted to migrate.”

The UK population has declined by almost 90% during the past 40 years. Captive breeding is helping to ensure that this species of dove does not face extinction. But it relies on donations and so we are always delighted when companies and individuals step up to the mark to help the project.

To learn more about the amazing work this charity is doing to help Turtle Dove populations, visit Turtle Dove Trust

Regenerative principles support more productive grasslandA longer growing season, better quality grass and improved pest control support overall forage production, and they are all advantages of following regenerative agriculture principles.

“One key pillar of regenerative agriculture is greater plant diversity,” says Limagrain’s forage crop manager John Spence. “And it’s an area where grassland farmers can reap the benefits by growing mixtures with more species that widen the growing period and help to combat more variable climate conditions.

“For example, clovers continue to grow in mid-summer when ryegrass varieties slow up. This increases the growing season. Clover also offers nitrogen-fixing benefits.”

Likewise, deeper rooted plants included in multi-species mixtures, such as chicory and plantain, will be more productive in drought conditions whilst also improving soil structure and health.

Improve ground cover

Keeping soil covered is another regenerative pillar – and one to focus on for improved grassland productivity. “Mixtures with improved ground cover, dense swards and few bare patches are less prone to poaching in winter on wet land,” he adds. “Including clovers and herbs alongside highly productive ryegrass varieties ensures mixtures are more robust in dry summers with good ground cover, as well as increased forage output and quality.

He encourages grassland farmers to avoid leaving swards fallow between reseeds. “We recommend that farmers avoid following grass with grass immediately, particularly if there’s a pest problem, and a six-month break is good. Instead, a winter forage crop such a stubble turnips and forage rape will maintain ground cover, help to break the pest cycle, and provide extra much-needed forage for livestock.”

He encourages grassland farmers to avoid leaving swards fallow between reseeds. “We recommend that farmers avoid following grass with grass immediately, particularly if there’s a pest problem, and a six-month break is good. Instead, a winter forage crop such a stubble turnips and forage rape will maintain ground cover, help to break the pest cycle, and provide extra much-needed forage for livestock.”

One of the main regenerative agriculture pillars is avoiding soil disturbance. “For grassland farmers this means direct drilling of new leys, minimum soil cultivation, and avoiding ploughing where possible. Overseeding is a good way of increasing productivity without cultivation”.

“Mixtures with tetraploid ryegrasses are good here as they complete well with existing grasses.”

Grassland farmers are already following many of the regenerative farming principles, but there’s more to be gained – specialist mixtures, forage break crops and improved practices will both support soil health and add to grassland productivity.

Financial support?

And there’s the added support from new SFI rules that could offer cash payments for making certain improvements, such as “NUM2: Legumes on improved grassland,” which offers £102/ha for introducing legumes such as white clover into existing temporary grass swards.

“It’s a win-win for many grassland farmers – more output from grassland and increased support for regenerative principles will support their businesses’ longer-term sustainability.”

Find out more about our grass mixtures here

Ian Foot: a pioneer in bringing quality wheats to marketQuality wheat breeding is losing a renowned figure as Ian Foot retires from the world of flour functionality and baking at leading plant breeders Limagrain UK, where he has headed up the quality wheat programme for the last 30 years.

Whilst Ian Foot’s retirement marks the end of an era, it also marks the beginning of a new chapter, led by a passionate and skilled successor. As the torch is passed on to Ewa Lagowska, the spirit of innovation and excellence in wheat quality breeding continues to thrive at Limagrain UK.

Whilst Ian Foot’s retirement marks the end of an era, it also marks the beginning of a new chapter, led by a passionate and skilled successor. As the torch is passed on to Ewa Lagowska, the spirit of innovation and excellence in wheat quality breeding continues to thrive at Limagrain UK.

Ian had an unconventional start to his journey in science. He didn’t like his history teacher at school, so he opted to take biology instead!

This led him to pursue biology at higher education, firstly at the Northeast Surrey College of Technology and subsequently at the West of Scotland Agricultural College, where Ian’s six-month industrial placement turned into a transformative few years at Throws Farm.

This led him to pursue biology at higher education, firstly at the Northeast Surrey College of Technology and subsequently at the West of Scotland Agricultural College, where Ian’s six-month industrial placement turned into a transformative few years at Throws Farm.

During this time, Ian not only gained valuable practical knowledge but also discovered his true calling. He returned to his studies with newfound zeal and completed a degree in agriculture, specialising in Crop Production. Armed with his newly acquired knowledge, he landed a position at Twyford Seeds, where he managed seed quality and pathology labs.

However, it was all change in the early 1990’s, when he found himself working for plant breeders Nickerson, who at that time had recently been acquired by Limagrain. Here he had the privilege of working under the mentorship of the esteemed wheat breeder, Bill Angus. Under Bill’s guidance, Ian honed his skills and became deeply involved in quality wheat breeding.

However, it was all change in the early 1990’s, when he found himself working for plant breeders Nickerson, who at that time had recently been acquired by Limagrain. Here he had the privilege of working under the mentorship of the esteemed wheat breeder, Bill Angus. Under Bill’s guidance, Ian honed his skills and became deeply involved in quality wheat breeding.

Ian took on the role of quality wheat manager, where he played a crucial role in developing quality programs that bridged the gap between end-user requirements and wheat breeding for the bread and biscuit sectors.

Working closely with wheat breeder Ron Granger, Ian spearheaded the development of the leading milling variety, Crusoe. Collaborating with the baker, Warburtons, Ian and his team had set out to find a wheat variety that could potentially replace the popular variety, Hereward. This variety had to meet Warburtons’ stringent quality requirements, including the quality of the flour, its functionality, baking performance and colour. For a variety to make a Group 1, it needs to deliver all this consistently.

The creation of Crusoe was a triumph. It not only met Warburtons’ high standards but also proved to be a resounding success in the market.

Today, more than a decade later, Crusoe remains one of the leading quality wheats, a testament to Ian’s visionary work and it has just been awarded the NIAB Variety Cup.

Ian Foot remains modest about his achievements and acknowledges the challenges of quality wheat breeding. The complexity of the task, with numerous independent variables to consider, makes it rare for a variety to tick all the boxes and endure in the competitive market.

Nevertheless, Ian’s passion for science, dedication to his craft, and commitment to improving agriculture have left a lasting impact on the industry and earned him a well-deserved place among the pioneers of quality wheat breeding.

Introducing ultipro seed treatment technologyBetaseed’s unique seed treatment Ultipro is designed to help sugar beet growers maximise their yields and profitability by improving the health and performance of their crops.

By protecting the seed and promoting early plant development, Ultipro can help growers establish a strong, healthy stand of sugar beets that can withstand environmental stresses and produce a high-quality crop. Ultipro has been independently tested for 3 years and is approved for use in the UK. It is available on the varieties; BTS SMART 9485 and BTS 1915.

The Limagrain UK portfolio of Betaseed varieties continues to offer a diverse range of varieties for individual growers’ consideration on the new RL 2024.

Find out more about our sugar beet portfolio here

Download the Betaseed Sugar Beet Variety Guide

Delivering success in sugar beetThe Limagrain UK portfolio of Betaseed varieties are proven to deliver successful performance, in trials and more importantly, on-farm.

Even in the recent erratic, testing seasons of drought and virus, BTS varieties have shown consistently high performance – delivering growers security in genetics.

As you will see from the enclosed BBRO Sugar Beet Recommended List for 2024, Betaseed varieties offer genetic diversity for a successful harvest;

BTS 1915 – continues to be the highest yielding variety in both treated and untreated trials, showing a resilience better than any other RL sugar beet variety.

BTS SMART 9485 – the first ALS herbicide tolerance variety from Betaseed, offering the highest yield potential for SMART CONVISO varieties, combined with improved disease and bolting resistance.

BTS 3020 – is an outstanding variety for the earlier and normal drilling situation with the lowest ESB figures available. It offers good yield combined with the highest sugar content and excellent disease resistance.

BTS 3610 – is one of only a few varieties that have achieved a NSB count of 0 over the 3-year data set – critical if bolting is a key consideration on your farm and offering robustness for earlier drilling.

INTRODUCING ULTIPRO SEED TREATMENT TECHNOLOGY

Betaseed’s unique seed treatment Ultipro is designed to help sugar beet growers maximise their yields and profitability by improving the health and performance of their crops. By protecting the seed and promoting early plant development, Ultipro can help growers establish a strong, healthy stand of sugar beets that can withstand environmental stresses and produce a high-quality crop. Ultipro has been independently tested for 3 years and is approved for use in the UK. It is available on the varieties; BTS SMART 9485 and BTS 1915.

The Limagrain UK portfolio of Betaseed varieties continues to offer a diverse range of varieties for individual growers’ consideration on the new RL 2024.

Find out more about our sugar beet portfolio here

Download the Betaseed Sugar Beet Variety Guide

Consistency is key to sugar beet successSugar beet plays an important part in the rotation because it provides consistent yields and is a genuine break crop, according to fourth generation farmer Peter Mahony, of R&D Mahony.

“We grow sugar beet because it is a spring-sown crop that contributes to weed control, particularly black grass, which can be problematic as our soils are mainly heavy clay which predisposes them to the weed.”

Mr Mahony’s variety of choice over the past three years has been BTS 1915, which he likes because it ‘ticks the box on consistent yield’. He has also grown BTS 1140 and BTS 3610.

“BTS 1915 fits well with our system despite the variety being susceptible to bolting, as we are growing the crop in heavy soils, so we do not usually drill until the second half of March.”

The Bury St Edmunds-based farm has been growing sugar beet since the mid-1960s, so there is plenty of crop management experience behind decisions, although Peter emphasises that every spring brings different challenges.

Sugar beet usually follows winter wheat and Peter’s strategy is to plough in the autumn, burn off volunteers with glyphosate, repeat this again in the spring and create a nice seedbed with good tilth.

His five-year average yield is 73t/ha, he reveals, remarking that this is a good result given the heavy soils the crop is grown in. However, last year, yields were lower due to the drought and beet moth issues.

“Whilst we have a had a few dry springs, this year we are also coping with March and April being unreasonably cold and very wet.

“Whilst we have a had a few dry springs, this year we are also coping with March and April being unreasonably cold and very wet.

“But we have to work with what we are given, and beet drilling was split with 7ha drilled on the 5th April and the remainder 18-19th April.

“We planted into very wet seedbeds, so we kept drilling depths shallow to conserve the tilth on the top.”

By the third week of May the crops were at the four to eight-leaf stage, and looking very healthy.

Peter goes on to share some of his ‘secrets’ of how he addresses some of the inherent challenges to get the most from sugar beet crops on his land.

“We find that quite often it can be too hot in the day to apply herbicides, so we prefer to go in the evening.

“If the machinery has been used for spraying cereals, we make sure it is given a good clean before it goes into sugar beet to prevent contamination.”

He has also adjusted his fertiliser strategy for sugar beet, to ensure the best results.

“When the crop emerges we like to apply 80kg/N/ha to give it a good push. However, although we use liquid N on the other crops in the rotation, it can cause scorch on sugar beet and also interfere with herbicide efficacy.

“As a result, we buy solid fertiliser especially for the sugar beet, which, as it is bought in small quantities, is expensive, but the end result is worth it.”

Lifting sugar beet can cause soil compaction which needs remedial work before the next crop goes in and Peter points out that the harvester, which weighs 40t, plus the tractor and trailer are all on the field at the wrong time of year.

“We normally try to have just two or three lifts, and then go into spring barley.”

“However, last year we managed to lift in mid-October, which worked well.”

One of the reasons behind this early lifting was because there was an attack of beet moth; last year also saw challenges from heat, drought and aphids.

“With BTS varieties, and particularly BTS 1915, we are able to achieve consistent yields. This means we know what we are going to get, even when prices are not so good.

“However, as we are now changing our tillage strategy, and will be using a Claydon drill, we will have to evaluate where – and whether – sugar beet will sit with the new regime.”

Farm facts:

Home farm: 133ha (330 acres)

Contract farm: 81ha (200 acres)

Soil: Heavy clay

Current rotation: Winter barley, winter wheat, beans, sugar beet, spring barley

Highest yields for third year running

The highest yielding variety on the Recommended List, BTS 1915 keeps its lead for the third year running at 103.9%.

“BTS 1915 is once again showing its ability to hold onto its exceptional yields across a range of locations and situations.”

“The consistency of performance of BTS 1915 is quite remarkable, and should give growers the reassurance that they are looking for when considering what variety to grow this year.”

“This significant yield advantage over any other variety on the RL – and also as the highest yielding variety in untreated trials at 106.5%, really proves the quality of the genetics behind the variety,” says Mr Granger.

BTS 1915 is not just about high yields however, he continues. “We recognise that varieties also need to establish well, have good bolting tolerance and robust disease resistance to succeed.”

BTS 1915 does have a good disease resistance profile but is not a variety to be considered for the early drilling situation as indicated by the red X (unsuitable for sowing before mid March), points out Mr Granger.

“We recommend the variety for the normal to late sowing period – mid March onwards, which for the majority of growers is the mean average drilling date on farm. ”

BTS 1915 Facts

• Bred by Betaseed, the Limagrain UK portfolio offers varieties to suit a range of situations and requirements:

• BTS 1915 – The highest yielding variety available

• Suitable for sowing Mid March onwards

• Good disease resistance

Find out more about our sugar beet portfolio here

Download the Betaseed Sugar Beet Variety Guide

Back your grasslandGrassland improvement is always a wise investment and despite some hikes in input prices there’s still no question on the payback from a reseed or repair.

Early summer is a key time in the grassland calendar. It’s when ‘big’ decisions are made – like timing of silage cuts to achieve the best quality or to maximise yield to fill the clamp.

“But it’s also time to assess sward and grass quality and make some decisions,” says Limagrain UK’s forage crops product manager John Spence.

So once first cut is completed, a visual assessment of the swards, together with yield and initial quality details, will give a good indication of whether silage targets have been met.

Fertiliser ‘fix’

If yields are down and the silage clamps are low after first cut then sward growth should be maximised in the short term.

“It might be a hard pill to swallow this year, but even with high input prices, the additional grass yield gained from fertilizer applications is worthwhile and more cost-effective than making up the shortfall in dietary energy with bought-in feed,” says Mr Spence.

Whilst reducing fertiliser applications might seem like an attractive idea, a 25% cut in nitrogen from an annual rate of 250kg/ha to around 185kg/ha is likely to reduce grass yields by around 2t/ha equivalent to a reduction in energy of around 22,000MJ/ha. This might save around £80/ha in fertiliser costs but the loss in energy from grass will cost around £600 to replace from energy in bought-in concentrates.

“And remember, concentrate feed prices are still high, so most farmers will see maximising milk from high quality forage as even more important this year.”

Oversowing the sward with a grass seed mixture – or clover – is another short to medium term grass improvement option, and soon after first cut is a good time to do this on any swards needing some ‘repair’.

Oversowing the sward with a grass seed mixture – or clover – is another short to medium term grass improvement option, and soon after first cut is a good time to do this on any swards needing some ‘repair’.

“Have a walk around the sward a few days after cutting it,” adds Mr Spence. “Look for gaps and broadleaved weeds. But also look at the grasses. There’s no need to worry about identifying the individual grass weeds but look for the proportion of ryegrass in a sward.”

Ideally, 70% of the grass plants should be ryegrass. If there’s less, productivity begins to be significantly compromised. “Examine a metre square area and work out the ryegrass population,” he adds. “If there’s between 70% and 80% perennial ryegrass content then overseeding – rather than a full reseed – can renovate a ley and extend its productive life.”

Correct mixture choice for overseeding is important as the newly sown grasses need to compete with the existing sward. A high inclusion of Tetraploid grasses is recommended as they tend to be larger seeded and more competitive with the established plants.

“Overseeding is also a great way of introducing or increasing the clover content in the sward,” he adds. “Sowing clover in May and June, when soil temperatures have warmed up, means the clover should establish quickly and be able to better compete with surrounding grasses. A pelleted clover, with a mix of clover leaf sizes, gives best results.”

Grass ‘shelf-life’

Grass leys are at their most productive in their first year – so a sward sown in 2023, should be at its most productive in 2024. “Fall off is gradual but inevitable. By year five, a ley’s productivity could be just 60% of year two and the dry matter yield from a grass sward can decrease by about five tonnes/ha from year 1 to year 4.

Ideally, 20% of grassland should be reseeded each year. This keeps grassland on a five year rota and offers the opportunity to maximise sward productivity.

Even with higher fertiliser and fuel prices, Mr Spence says that the cost of a reseed is easily justified and will pay for itself in improved output from the sward in little over a year.

“It costs between £550 a hectare and £850 a hectare to reseed, depending on whether it’s an overseed or a full reseed,” he says. “But the dry matter output and forage quality should be significantly improved. The new ley should produce more than 33,000MJ per hectare of energy, which is enough to produce 6300 litres of milk. At 40p a litre, this is more than £2500 in milk value. So there’s no issue over justifying the cost.”

He points out the value of choosing a high quality tried-and-tested grass seed mixture suited to the farm and the sward’s purpose makes economic sense.

“It costs the same to sow an average grass seed mixture and a high quality proven mixture. Between 25% and 30% of the reseed cost will be spent on seed, if you opt for a high quality mixture, or around 20% for a standard mixture” he says.

“So there’s a marginal difference in price but on farm trials with new varieties and mixtures show a big difference in yield and feed value which farmers can take advantage of.”

Reseed timing

Reseeding in spring tends to be less popular than in autumn, primarily because it means taking a field out of production during peak grass growing time, despite warmer conditions favouring good establishment and less chance of competition from weeds.

“Less availability of pesticides has altered reseeding decisions. We can’t rely on their use in reseeds, so instead we’re looking more to a rotation to break the bug cycle to help ensure a successful reseed.”

One option may be a quick growing brassica such as Skyfall, sown in May after first cut silage and giving several high protein rounds of grazing, starting as early as late July when the grass growth has slowed down. “We call this crop a bounce-back brassica as it can be grazed, closed up and after an eight-week regrowth, re-grazed ahead of an autumn reseed.”

One option may be a quick growing brassica such as Skyfall, sown in May after first cut silage and giving several high protein rounds of grazing, starting as early as late July when the grass growth has slowed down. “We call this crop a bounce-back brassica as it can be grazed, closed up and after an eight-week regrowth, re-grazed ahead of an autumn reseed.”

For those looking for a second cut or grazing round prior to a reseed, a kale or brassica hybrid or stubble turnips sown in July or August will provide a grazing crop in autumn and winter ahead of a spring reseed.

“There are lots of options when it comes to maximising output from grassland, and cutting costs in this area is false economy. There are many other areas to look at before making cuts here.

“And bear in mind that reseeding, oversowing and fertiliser use go together. Younger, healthier grasses will make better use of fertiliser applications than older swards, which means that more fertiliser is turned into grass and feed value in a healthy fresh grass sward.”

Find out more

To see the full range of Sinclair McGill mixtures and find your nearest distributor, click here

To download the Sinclair McGill Grass and Forage Handbook, click here

To find out more about LG Skyfall Bounce Back Brassica, and download a free Growers’ Guide.